- Welcome to the Ford Mustang forum built for owners of the Mustang GT350, BOSS 302, GT500, and all other S550, S197, SN95, Fox Body and older Mustangs set up for open track days, road racing, and/or autocross. Join our forum, interact with others, share your build, and help us strengthen this community!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SN95 RinerAutomotive's CAM-T Mustang Build Thread Profile - SN95 Mustangs

- Thread starterRinerAuto

- Start date

This site may earn a commission from merchant affiliate links, including eBay, Amazon, and others.

More options

Who Replied?- Thread starter

- #82

Well the offseason work has begun. I took the whole week before Christmas off to get as much work as I could done. I know the week after Christmas is always full of catching up with friends and family.

The freshly rebuilt 306 bottom end went onto the engine stand and got all the original goodies reinstalled (TW 11R 170 and Holley Systemax). I did a DIY baffle on the engine pan. I don't see the need for going to a road race pan for autocross, plus I don't have much room under the engine for a larger pan. The fuel injectors were cleaned and checked by Injector Pulse, who is local to me. Injectors all checked out good and now have the correct spray pattern after cleaning.

Next on the engine agenda is figuring out the distributor less ignition system. I designed up a trigger wheel that will get machined along with the harmonic dampener for a press on fit. I have godzilla coils, explorer cam sync, and explorer crankshaft position. Just now need to figure out coil mounting. I didn't like the tall valve covers and will need the extra room for the coils, so I bought Trick Flow valve covers.

After engine assembly was time to remove the old engine and suspension. I dropped the whole assembly out the bottom onto a furniture dolly then used the engine hoist to lift the car up while I rolled out the engine. It all went very smoothly.

Last up was suspension mock up time. I test fitted my upper control brackets that I designed and had SendCutSend make. Everything fit perfectly, but saw some room for improvement. With the upper control arm mounted I test fit the rest of the "stock" suspension and this is when I realized I screwed up somewhere. I had positive camber and a lot of it. My upper arm was as short as possible, the only option is to increase the lower control arm length. I'm still not sure why it didn't match my model. But I am working on a plan to do lower control arms also that will get me better geometry anyway.

The reason I didn't do lower control arms in the first place is because I didn't feel confident in my welding for that critical of a component yet. But I found some circle track parts that look like they are going to work even better.

I did buy a Tig Welder during black friday, just need to set it up and practice and practice some more.

The freshly rebuilt 306 bottom end went onto the engine stand and got all the original goodies reinstalled (TW 11R 170 and Holley Systemax). I did a DIY baffle on the engine pan. I don't see the need for going to a road race pan for autocross, plus I don't have much room under the engine for a larger pan. The fuel injectors were cleaned and checked by Injector Pulse, who is local to me. Injectors all checked out good and now have the correct spray pattern after cleaning.

Next on the engine agenda is figuring out the distributor less ignition system. I designed up a trigger wheel that will get machined along with the harmonic dampener for a press on fit. I have godzilla coils, explorer cam sync, and explorer crankshaft position. Just now need to figure out coil mounting. I didn't like the tall valve covers and will need the extra room for the coils, so I bought Trick Flow valve covers.

After engine assembly was time to remove the old engine and suspension. I dropped the whole assembly out the bottom onto a furniture dolly then used the engine hoist to lift the car up while I rolled out the engine. It all went very smoothly.

Last up was suspension mock up time. I test fitted my upper control brackets that I designed and had SendCutSend make. Everything fit perfectly, but saw some room for improvement. With the upper control arm mounted I test fit the rest of the "stock" suspension and this is when I realized I screwed up somewhere. I had positive camber and a lot of it. My upper arm was as short as possible, the only option is to increase the lower control arm length. I'm still not sure why it didn't match my model. But I am working on a plan to do lower control arms also that will get me better geometry anyway.

The reason I didn't do lower control arms in the first place is because I didn't feel confident in my welding for that critical of a component yet. But I found some circle track parts that look like they are going to work even better.

I did buy a Tig Welder during black friday, just need to set it up and practice and practice some more.

Your Car is awesome, thought it looked familiar I ran the last couple of events at Pungo.Well the offseason work has begun. I took the whole week before Christmas off to get as much work as I could done. I know the week after Christmas is always full of catching up with friends and family.

The freshly rebuilt 306 bottom end went onto the engine stand and got all the original goodies reinstalled (TW 11R 170 and Holley Systemax). I did a DIY baffle on the engine pan. I don't see the need for going to a road race pan for autocross, plus I don't have much room under the engine for a larger pan. The fuel injectors were cleaned and checked by Injector Pulse, who is local to me. Injectors all checked out good and now have the correct spray pattern after cleaning.

Next on the engine agenda is figuring out the distributor less ignition system. I designed up a trigger wheel that will get machined along with the harmonic dampener for a press on fit. I have godzilla coils, explorer cam sync, and explorer crankshaft position. Just now need to figure out coil mounting. I didn't like the tall valve covers and will need the extra room for the coils, so I bought Trick Flow valve covers.

After engine assembly was time to remove the old engine and suspension. I dropped the whole assembly out the bottom onto a furniture dolly then used the engine hoist to lift the car up while I rolled out the engine. It all went very smoothly.

Last up was suspension mock up time. I test fitted my upper control brackets that I designed and had SendCutSend make. Everything fit perfectly, but saw some room for improvement. With the upper control arm mounted I test fit the rest of the "stock" suspension and this is when I realized I screwed up somewhere. I had positive camber and a lot of it. My upper arm was as short as possible, the only option is to increase the lower control arm length. I'm still not sure why it didn't match my model. But I am working on a plan to do lower control arms also that will get me better geometry anyway.

The reason I didn't do lower control arms in the first place is because I didn't feel confident in my welding for that critical of a component yet. But I found some circle track parts that look like they are going to work even better.

I did buy a Tig Welder during black friday, just need to set it up and practice and practice some more.

PatientZero

@restless_performance

What did you get?I did buy a Tig Welder during black friday, just need to set it up and practice and practice some more.

- Thread starter

- #85

Thanks. I somehow missed your car at Pungo. I usually try to talk to all the Mustang guys. Hopefully you can make it some of our events this year although no longer will be at Pungo.Your Car is awesome, thought it looked familiar I ran the last couple of events at Pungo.

- Thread starter

- #86

I got the Primeweld TIG225X. Nothing too crazy but not cheap junk.What did you get?

- Thread starter

- #87

- Thread starter

- #88

As mentioned in a previous post I screwed up on my suspension design. The stock lower control arm is not going to work. I was looking at some circle track parts but I'm just going to build my own. That way I get exactly what I want instead of keep doing these compromises. I think I'm also going to do a few tweaks to my upper control arm bracket as I discussed in the video.

So if video is more of your thing here is the link:

So if video is more of your thing here is the link:

- Thread starter

- #89

I'm going to build my own lower control arms. So while I wait for those parts to be delivered, I switched gears to working on my distributorless ignition setup for the small block ford. Here are the basics:

I accidentally posted the video early so enjoy!

- Explorer crank and cam position sensors

- Explorer timing cover

- Godzilla ignition coils

- EECV computer from a crown vic

- Custom trigger wheel I designed and got cut by SendCutSend, then got balance and trigger wheel machined for press fit

- Reworked 94 V6 fender harness

- Reworked 94 5.0L engine harness

- Custom coil bracket to mount overtop the valve covers

I accidentally posted the video early so enjoy!

- Thread starter

- #90

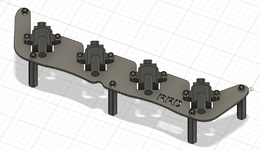

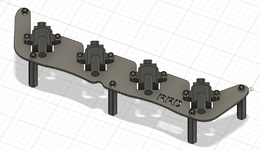

As I mentioned, I plan to use the 7.3L Godzilla coils for my coil near plug setup. There are options out there to mount coils on a SBF but they are quite expensive. While I like the idea of welding bolt pads onto of the valve covers I didn't want to mess up the brand new trick flow coils and I haven't welded aluminum before. So that leaves a bolt on option. My plan is to design a plate and then use standoffs to mount it above the valve cover. After a little bit of cardboard aided design and transferring it to Fusion 360, I got this:

I have really come to like designing in Fusion 360 and then uploading to SendCutSend to get plates cut. Along with parts from McMaster-Carr I get this awesome looking setup.

I think this really turned out great. Now this does require an intake manifold spacer, which I already had installed.

Like video format, check out my YouTube channel

I have really come to like designing in Fusion 360 and then uploading to SendCutSend to get plates cut. Along with parts from McMaster-Carr I get this awesome looking setup.

I think this really turned out great. Now this does require an intake manifold spacer, which I already had installed.

Like video format, check out my YouTube channel

PatientZero

@restless_performance

Looks awesome

Looking good cant wait to see it up close.

- Thread starter

- #93

Trying out another tire manufacturer. When I switched to CAM-T from C-prepared I started with the Falken RT660. The following year I tried out the Nankang CR-1. This year I'm trying out the new Bridgestone RE-71RS. I am also dropping down from 315/30R18 to 295/30R18. This tire will be a better match for the 10.5 wheels. One day I step up to 11 or 12 inch wheels, but for now this is what I have.

I had no issues with any of the tires I have ran. I think they are all great tires and really come down to car setup and driver. The RT660 I liked that the tires were symmetrical and could be rotated on the wheel. The RT660 lasted a full season with 2 drivers but heat cycled out even with plenty of tread left. The Nankang's were asymmetrical which allowed them to be installed any where on the car which helped with tire wear. But they couldn't be rotated on the wheel, so the outside edge got really worn out. These tires wore all the way down to the wear bars, while still being competitive until the last event (but it was also cold).

Hopefully these Bridgestones perform just as well or better than the other tires.

I had no issues with any of the tires I have ran. I think they are all great tires and really come down to car setup and driver. The RT660 I liked that the tires were symmetrical and could be rotated on the wheel. The RT660 lasted a full season with 2 drivers but heat cycled out even with plenty of tread left. The Nankang's were asymmetrical which allowed them to be installed any where on the car which helped with tire wear. But they couldn't be rotated on the wheel, so the outside edge got really worn out. These tires wore all the way down to the wear bars, while still being competitive until the last event (but it was also cold).

Hopefully these Bridgestones perform just as well or better than the other tires.

PatientZero

@restless_performance

I'll be curious how you like the switch from the 315's to 295's. I've been running 295's on 10.5 wheels for the last few years and now have the 295's on a 11. I wish I was able to try out all the combos back to back but I'm poor, lol.

- Thread starter

- #95

I'll make sure to update. A lot of people have said it will be better...we'll see. Tires are too expensive, but necessary.I'll be curious how you like the switch from the 315's to 295's. I've been running 295's on 10.5 wheels for the last few years and now have the 295's on a 11. I wish I was able to try out all the combos back to back but I'm poor, lol.

- Thread starter

- #96

I just love staring at this suspension. I designed and built that. It's such a shame it will be hidden under the fenders. The suspension build is getting so close to completion. Waiting on a lower ball joint to be delivered. Then I can install wheels and put the car on the ground for the first time in over 2 months. New video coming this Friday hopefully with the car sitting on tires

- Thread starter

- #97

The car is on the ground! So exciting. Still have a few things to do to button up the SLA build: sway bar mount, brake line, ABS sensor. Then can break it all down fully weld it out and paint.

I'm thinking I'll need to get a slightly extended upper ball joint to help the brake bleeder clear the upper control arm during turn in.

Additionally, since I am now wider than stock I'm running out of thread on the outer tie rod. I have the MM bumpsteer kit which changes it to a 5/8 rod end. I found this site https://www.racecraft.com/ has different length sleeves. The required sleeve needs to be a M14 for the inner tie rod to 5/8 for the rod end.

I'm thinking I'll need to get a slightly extended upper ball joint to help the brake bleeder clear the upper control arm during turn in.

Additionally, since I am now wider than stock I'm running out of thread on the outer tie rod. I have the MM bumpsteer kit which changes it to a 5/8 rod end. I found this site https://www.racecraft.com/ has different length sleeves. The required sleeve needs to be a M14 for the inner tie rod to 5/8 for the rod end.

- Thread starter

- #98

I received the tie rod sleeves from RaceCraft, but missed that they were left hand thread. The MM bumpsteer kit uses right hand rod ends...oops. So another item to buy  . It's all the small hardware that just nickels and dimes you.

. It's all the small hardware that just nickels and dimes you.

But on a good note, Coilovers! I bought double adjustable shocks from JRi Shocks. They were pricey, but I wanted something that will be competitive. For springs I bought some 400lb Hypercoil 2.5" diameter 10 inch long springs. With my motion ratio the 400lb spring gives a natural frequency of ~1.7 Hz. I wanted to be a little softer sprung than the car currently is with the H&R Super Race springs (>1000lb?).

Crunch time is on, less than 2 weeks until first event that I've signed up for

But on a good note, Coilovers! I bought double adjustable shocks from JRi Shocks. They were pricey, but I wanted something that will be competitive. For springs I bought some 400lb Hypercoil 2.5" diameter 10 inch long springs. With my motion ratio the 400lb spring gives a natural frequency of ~1.7 Hz. I wanted to be a little softer sprung than the car currently is with the H&R Super Race springs (>1000lb?).

Crunch time is on, less than 2 weeks until first event that I've signed up for

Nice, you running at cherry point?

- Thread starter

- #100

I'm hopingNice, you running at cherry point?

Trying to get the car thrown back together as quickly as possible. Going to have to do a few compromises in order to be ready. If the car runs and drives by this weekend then I should be able to make it, if not then I don't know.

Similar threads

- Replies

- 0

- Views

- 228