First time poster here, I have an 04 GT with the primary focus of AutoX, until I do some more upgrades and feel more comfortable with taking it to an actual track. I haven't ran the car but a few times but I consistently have issues with the rear suspension not allowing me to exit a turn under power, always lifts the inside rear. My current setup is pretty basic, as I don't have much money to throw at the car with everything else in life going on. I have H&R Race springs, tubular control arms with poly bushings (soon to be modified for heims on one end), MM CC plates, MM full length SFC's, SR Sway bars and racing seats with 5pt cage and harnesses to keep me from sliding all over, running 18x10s with 295s square setup. MM Panhard kit is on the FedEx truck as I type this.

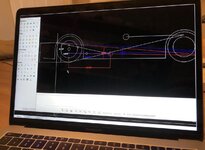

I have done some research and cant find anyone that has converted the rear end to symmetric 3 link setup. I've seen the Steeda 5link kit but I'm not a fan of the upper link mounting to the side of the OE torque box, the evolution 3 link kit looks more like what I want but not a fan of their frame mount either, and I'm not sold on the PM3L. I also want something adjustable that doesn't hang down low like the Torque arm.

Is there a specific reason the upper link should be offset to the right or would a centered link offer more consistent Left/Right turning characteristics?

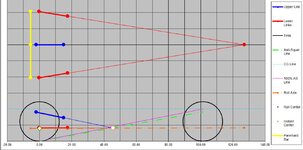

I'm currently targeting 65% antisquat for nominal position with adjustment means on both ends, is that a good target or should I go higher?

Once I get the Panhard installed I plan on cutting out the upper torque boxes to fab my upper frame mount, so I'm looking to get any advice I can from now until then.

thanks

-Randy

I have done some research and cant find anyone that has converted the rear end to symmetric 3 link setup. I've seen the Steeda 5link kit but I'm not a fan of the upper link mounting to the side of the OE torque box, the evolution 3 link kit looks more like what I want but not a fan of their frame mount either, and I'm not sold on the PM3L. I also want something adjustable that doesn't hang down low like the Torque arm.

Is there a specific reason the upper link should be offset to the right or would a centered link offer more consistent Left/Right turning characteristics?

I'm currently targeting 65% antisquat for nominal position with adjustment means on both ends, is that a good target or should I go higher?

Once I get the Panhard installed I plan on cutting out the upper torque boxes to fab my upper frame mount, so I'm looking to get any advice I can from now until then.

thanks

-Randy

Last edited: