- Thread starter

- #161

- 6,405

- 8,307

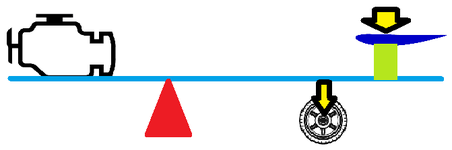

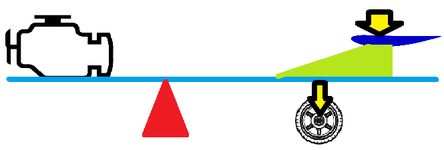

Yep, when cars started flying is when the restrictor plates started, especially after Bobby Allison's flight at Talledega where parts of the car actually went into the stands. One reason you don't see Indycars on some tracks is because spectators were killed in both CART and IRL races at superspeedways. I'd love to see Indy cars at Daytona... never gonna happen. They hit about 245 at Indy, they'd probably bounce 275 at Daytona.Restrictor plates in NASCAR have one purpose. To keep the cars out of the stands.

The trade off is that it means " closer" racing, but it creates too many wrecks and not enough competition. Too much depends on luck.