Dave_W

Cones - not just for ice cream

Believing the first part of that probably won't get you into trouble. But the second part is completely wrong, and suffers from the common fallacy that no body roll means no weight transfer (among other issues).Saw this on another forum that I thought was interesting:

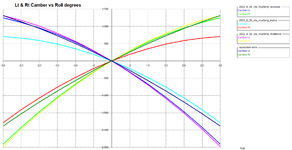

The amount of lateral weight/load transfer in a corner is a function of the lateral g-load, the CG height, and the track width. That's it. The roll center location does not affect the total amount of load/weight transfer. What the RC location does do is influence how much of the total load transfer goes through the suspension links directly (geometric transfer) versus how much goes through the springs, ARBs, and shocks (elastic transfer). If the RC and CG are at the same place, all the load transfer is geometric and none is elastic. There is no body roll because no load transfer happens through the springs, ARBs, and shocks - but there is load transfer, it's going through the suspenion links/arms. As the RC moves away from the CG, some of the load transfer changes from geometric to elastic, and body roll occurs.

Also note that geometric load transfer happens instantly, while elastic load transfer is slowed or "timed" by roll stiffness and shock valving - the initial energy of the load transfer is absorbed by the springs & ARBs until the suspension reaches steady-state, and shock valving changes how long it takes to get to steady-state (wavy-hands simplification happening here).

As the RC moves up from ground level, a portion of the lateral load transfer of the sprung mass starts to become a vertical force at the contact patch. This is sometimes referred to as "jacking force" and can reduce grip. Also, higher RC tends to introduce lateral tire scrub with lateral g-loading, which can create increased tire wear and dynamic toe change.

This does a good job explaining the force components -

Tech Explained: Roll Centre

I got a lot of "aha" moments when I first read this; read through all the pages (original site is gone) -

Dynamic Load Transfer

How weight (or load transfer) affects handling of a racing car, and terms used to describe load transfer

web.archive.org