3V Swapped New Edge

Specs & Mods

- Ownership Status

- Currently Own

- Year

- 2000

- Transmission

- Manual

- Mods - Handling

- Maximum Motorsports K-Member, Tubular control arms (all), front coilover/adjustable struts, 17x10" Konig wheels with 275/40r17 Falken RT660's, Cobra brake upgrade all around, CC Plates, subframe connectors, BMR 25mm rear sway bar, battery relocation.

- Mods - Power

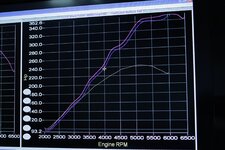

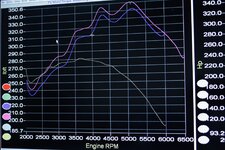

- 3V 4.6 Swap. Eagle Rods and Mahle flat-top pistons (.020" over), ported heads, stainless valves, 11:1 compression, Comp Cams 127500 w/ lockouts, aluminum flywheel, UD balancer, '13-'14 GT500 oil pump/pickup/windage tray/oil pan, BBK longtubes, 2.5" BBK off-road H-pipe, Bassani cat-back, cobra fuel pumps, Cobra 90mm MAF and fabricated CAI. Made 352HP and 350TQ to the wheels.

- Background & Plans

-

I've always loved Mustangs and had a 1987 T-Top Hatchback in high school that my dad and I swapped a 351W into. Caught the bug to do some track driving and growing up in a hot rodding household, V8 was the only way to go. I had an absolute blast the first year. Went to Waterford Hills a handful of times and Gingerman once, and even threw in an Autocross event. But, after a season of track driving it was apparent I needed more HP. Building the 2V was an option but wasn't going to deliver all that much for the investment. Then I met Dewayne Logan when he posted a rear sway bar for sale. He showed me his 3V swapped cars and after some research decided that was the way to go, as it would be 100# lighter than the iron 2V and a coyote, and could put 350hp+ to the rear wheels, N/A. And, with the cam phasers locked out and a little finagling you can run the 3V engine on the 2V ECU, saving me from having to buy a control pack. With the aluminum block 3V installed, the k-member swap and the battery relocation I estimated I've taken ~150# off the nose of the car, and I can definitely feel it.

I bought the motor on facebook marketplace. He sent me a video of the engine running in the car, however it must have been an old video... When I finally went to install the cams 3 months later I found that the motor was a mess inside. The cam towers were scored up and also had one bent connecting rod. Rather than finding a new engine, I accelerated my plans for the engine by a year and dove in. Had the block honed and cleaned up at Livernois, found some used heads on marketplace, ordered some forged rods and pistons and got to work porting the cylinder heads- which mostly consisted of cleaning up casting flash and sharp edges in the ports and un-shrouding the valves.

A few other things that go along with this engine swap are some wiring modifications as various sensors are in different places, adapting a Cobra TB to the 3V intake, plumbing in the IAC, and welding 3V flanges onto the 2V headers, since nobody makes a header for this swap. All in all it's pretty straight forward. Luckily I had Dewayne guiding me through some of the aspects of it that are not intuitive, such as how to modify the cam phasers to make the cam sensor work for this ECU.

I installed Ferrea stainless valves and Comp Cams 127500 cams with the phasers locked out on a 102º ICL. The compression ratio ended up being 11:1 and with the stock intake manifold, cobra TB and longtube's it made 352HP and 350lb.ft. to the wheels. Not bad for 285ci! I have an FRPP intake manifold and Accufab TB arriving soon so hopefully we can get it on the dyno one last time before the snow flies and see what she makes.

Still lots more to do. This winter I'll be working on more suspension mods, chassis stiffening, roll bar and seats. And the plan is to participate in mostly HPDE events and some SCCA Time Trials.