I was at Road Atlanta with Chin on June 24th and 25th trying out a brand new set of Michelin Cup2R tires. This was my first experience with R compound tires as I had been running PS4S and Bridgestone Potenza Sport tires which are both 300TW. The Cup2R tires are 140TW. Here are my observations:

Cup2R is super sticky and picks up a ton of debris. Thinking now I should trailer the tires to the track and put on in the paddock. Driving these tires on the road they look like a lint brush that has been rolled across a gravel road.

On the track the Cup2R stick! Posted my personal best of 1.39.4 first session out. Probably could have done better with practice but after that one solo session, I was giving rides to friends and family and drove more conservatively the balance of the weekend. Still consistently posted 1.40 to 1.42 times and didn’t feel close to the edge.

Tires give no warning at the edge of grip but recover almost instantly with a slight throttle release and/or steering correction. Felt very safe.

Was able to go much deeper into braking zones with a lot of confidence.

The jury is still out on tire wear. Had an engine cooling issue on Saturday and missed the afternoon sessions. Was back on the track for Sunday but didn’t do the happy hour. So all-in-all only have the equivalent of one full track day on the tires. Wear looks fairly even running -3 deg front and -2 deg rear camber. I’m sure these would give a full weekend of service. But not sure if these will last 2 full weekends or not. I think they probably will. I’m going to give them a try to see. I’ve got a square set-up so definitely would need to rotate.

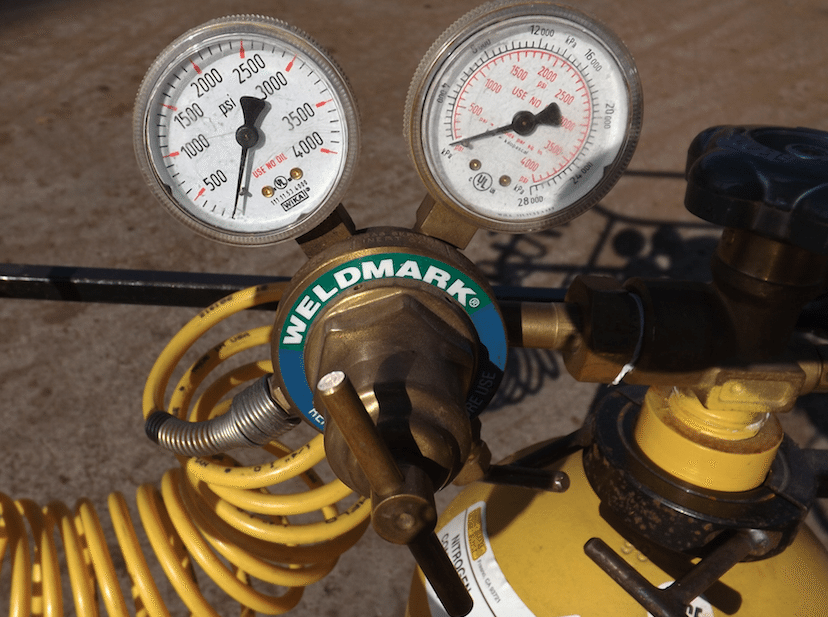

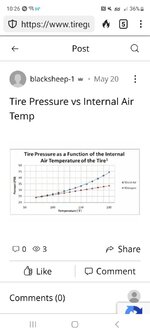

Managing tire pressure is a challenge. Michelin says these tires should not be run cold below 29PSI and hot should go to 39psi max depending on car weight. I started at 29 psi and ran a few easy laps to build heat and pressure. Once the tires got to 33 psi, I started running fast laps. Probably after 4 or 5 more laps psi would hit 39-40. 37 psi seemed to give the best grip for my car. But the only way to keep the pressure at 37 psi would be to run some laps, Pit, adjust pressure, and go back out. I’m running straight air. Wonder if Nitrogen fill would help? Any one have experience with pressure variation with nitrogen filled R-comp tires?

Bottom line: Expensive tire. Lots of smiles per dollar.

Questions and comments, Please.

Cup2R is super sticky and picks up a ton of debris. Thinking now I should trailer the tires to the track and put on in the paddock. Driving these tires on the road they look like a lint brush that has been rolled across a gravel road.

On the track the Cup2R stick! Posted my personal best of 1.39.4 first session out. Probably could have done better with practice but after that one solo session, I was giving rides to friends and family and drove more conservatively the balance of the weekend. Still consistently posted 1.40 to 1.42 times and didn’t feel close to the edge.

Tires give no warning at the edge of grip but recover almost instantly with a slight throttle release and/or steering correction. Felt very safe.

Was able to go much deeper into braking zones with a lot of confidence.

The jury is still out on tire wear. Had an engine cooling issue on Saturday and missed the afternoon sessions. Was back on the track for Sunday but didn’t do the happy hour. So all-in-all only have the equivalent of one full track day on the tires. Wear looks fairly even running -3 deg front and -2 deg rear camber. I’m sure these would give a full weekend of service. But not sure if these will last 2 full weekends or not. I think they probably will. I’m going to give them a try to see. I’ve got a square set-up so definitely would need to rotate.

Managing tire pressure is a challenge. Michelin says these tires should not be run cold below 29PSI and hot should go to 39psi max depending on car weight. I started at 29 psi and ran a few easy laps to build heat and pressure. Once the tires got to 33 psi, I started running fast laps. Probably after 4 or 5 more laps psi would hit 39-40. 37 psi seemed to give the best grip for my car. But the only way to keep the pressure at 37 psi would be to run some laps, Pit, adjust pressure, and go back out. I’m running straight air. Wonder if Nitrogen fill would help? Any one have experience with pressure variation with nitrogen filled R-comp tires?

Bottom line: Expensive tire. Lots of smiles per dollar.

Questions and comments, Please.

Last edited: