Looking for a sanity check here before I pull the engine for tear down and inspection. For the last couple events, I’ve had trace amounts of oil in the coolant expansion tank. Not a lot of oil - just enough to form a nasty colored line around the edge of the tank, but it’s definitely oil. The cooling system seems to be over-pressurizing as well and will burp coolant out the cap when pushed for more than a couple laps. Temperatures are good - nothing over 205 or so at the point the system would push coolant out the cap. Engine oil is clean from what I can tell - no milky white filler cap, dipstick is clean and clear. And the thing is running as strong as it ever has - absolutely no performance concerns.

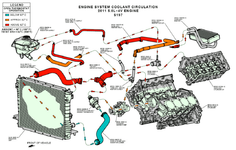

My initial suspect is a cylinder head gasket, but want to see if there’s anywhere else on these engines that could cross-contaminate that perhaps I’m missing? I’m using the Ford Performance oil cooler adapter on the block for a remote mount filter and cooler ruling out that possibility.

This is a Gen3 block with GT500 oil pump, which makes a LOT of oil pressure. Gen1 heads, which have a smaller oil passage through the head gasket than the later gen heads. Could the high pressure with smaller passage have compromised the head gasket??

I really don’t want to pull the engine right now with the thing running so well, but don’t want to cause bigger issues by not addressing it.

My initial suspect is a cylinder head gasket, but want to see if there’s anywhere else on these engines that could cross-contaminate that perhaps I’m missing? I’m using the Ford Performance oil cooler adapter on the block for a remote mount filter and cooler ruling out that possibility.

This is a Gen3 block with GT500 oil pump, which makes a LOT of oil pressure. Gen1 heads, which have a smaller oil passage through the head gasket than the later gen heads. Could the high pressure with smaller passage have compromised the head gasket??

I really don’t want to pull the engine right now with the thing running so well, but don’t want to cause bigger issues by not addressing it.