- Welcome to the Ford Mustang forum built for owners of the Mustang GT350, BOSS 302, GT500, and all other S550, S197, SN95, Fox Body and older Mustangs set up for open track days, road racing, and/or autocross. Join our forum, interact with others, share your build, and help us strengthen this community!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Post your tow strap/hook setup

- Thread starterbronco100

- Start date

This site may earn a commission from merchant affiliate links, including eBay, Amazon, and others.

More options

Who Replied?Hi Stan, The ZL1 website doesn't seem to have a picture of the rear tow hook, but you can buy it by selecting from their pull-down menu.I did not see this rear hook on the ZL1 site. I guess that mounts to the rear bumper beam? I want one.

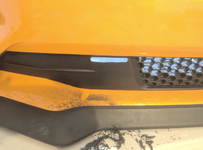

Here's a photo of the rear tow hook attached to my rear bumper bar:

Perfect, thanks!Hi Stan, The ZL1 website doesn't seem to have a picture of the rear tow hook, but you can buy it by selecting from their pull-down menu.

Here's a photo of the rear tow hook attached to my rear bumper bar:

View attachment 88699

Bill Pemberton

0ld Ford Automotive Racing Terror

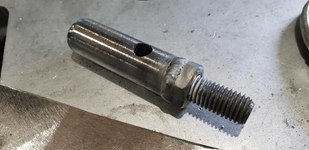

You gotta love the Mach 1 set -up , following the lead from Porsche or other makes where you just screw it right into a receptacle made at the factory. I still have the one from my Silver Mach 1 and it takes maybe 5 minutes to put on , max ( more like 2, but trying not to exaggerate ).

cholmes1

400lb Gorilla

Would you share a picture of the installation with the bumper cover on, please?Hi Stan, The ZL1 website doesn't seem to have a picture of the rear tow hook, but you can buy it by selecting from their pull-down menu.

Here's a photo of the rear tow hook attached to my rear bumper bar:

View attachment 88699

I see the rear beam replacement in favor of the tubing with tow hook, any cutting welding or just remove/install fasteners? I also like you brake cooling tube adaptors in the front bumper cover, what are those?Watson/FRPP for me

View attachment 88765

With the red loop removed the black attachment point blends into the background of most plates.

View attachment 88766

View attachment 88767

View attachment 88768

cholmes1

400lb Gorilla

No welding is required for the beam and loops, but you do have to cut the bumper cover. You would also need to cut/modify the foam bumper backing if you want to keep it in the front.I see the rear beam replacement in favor of the tubing with tow hook, any cutting welding or just remove/install fasteners? I also like you brake cooling tube adaptors in the front bumper cover, what are those?

The brake duct cooling is standard on the Laguna Seca. The OEM is 3” and I upgraded to the 302S/R 4” ducts. It requires removal of the windshield fluid bottle on the driver side and new 4” back backing plates. I got my ducts through Watson back when they existed for sale and the backing plate was from Fabman on TMO.

Thanks, the rearNo welding is required for the beam and loops, but you do have to cut the bumper cover. You would also need to cut/modify the foam bumper backing if you want to keep it in the front.

The brake duct cooling is standard on the Laguna Seca. The OEM is 3” and I upgraded to the 302S/R 4” ducts. It requires removal of the windshield fluid bottle on the driver side and new 4” back backing plates. I got my ducts through Watson back when they existed for sale and the backing plate was from Fabman on TMO.

Thanks, the rear tubular bumper beam looks good and solves the tow loop problem. This may make the winter project list.No welding is required for the beam and loops, but you do have to cut the bumper cover. You would also need to cut/modify the foam bumper backing if you want to keep it in the front.

The brake duct cooling is standard on the Laguna Seca. The OEM is 3” and I upgraded to the 302S/R 4” ducts. It requires removal of the windshield fluid bottle on the driver side and new 4” back backing plates. I got my ducts through Watson back when they existed for sale and the backing plate was from Fabman on TMO.

There is a Roush lower driving light kit that has a molded trim piece requiring cutting away the bisecting horizontal trim bar making the lower opening plenty big enough to route a 4” adaptor and tubing. It may be more functional, bigger is always better?

PatientZero

@restless_performance

cholmes1

400lb Gorilla

@Boss4Me The rear bumper does not have a foam core support. It is simply plastic bumper cover and bolt-on rear beam. The DOT requires foam up front to meet pedestrian and low speed crash requirements. I scrapped my front foam before final mounting as it was more trouble than it was worth.

The front bumper beam is different. It has to be unbolted and cut off before you can mount the front bar. From the factory the front beam is spot welded and bolted in place. Depending upon the spot welding, you may have only a couple that can be easily broken by hand/pry bar, or, as in my case, it was nearly a full 1” bead weld above and below the frame mount that required both drilling and cutting to remove. An unexpected PITA.

All that to say, the rear tow beam was MUCH easier to install in my setup. The cutting of the bumper cover is more tedious than difficult. If you are not overly concerned about aesthetics it can be done quickly. I was very much concerned, so it took about two hours to get the holes just large enough for the female tow loop to pass through the plastic cover without a gap.

Brake ducts are a bit of a mix. I would certainly not say “bigger is always better.” I have many photos showing 302R/S race teams using bumper duct block off plates to keep some heat in the pads and rotors. The amount blocked off seems to be very track dependent. My car is used for occasional mountain road rallies (point-to-point) and a singular sprint event each year. Not road course racing. In my case the 302S/R 4” ducts are overkill and purely to add a piece of limited racing equipment to my car. They were not needed to address brake cooling issues. If anything, they often run too cool and I am working on blocking plates similar to the race teams. I also think the 302S ducts look better than the OEM 3” units.

Thank you for the questions, this is the motivation I need to put the steps and photos for both projects in my build thread

If more questions arise let me know. The tow beams can both be completed in a day. The ducts likely will require their own day depending upon your access to the underside. I have a lift so it only took a few hours.

The front bumper beam is different. It has to be unbolted and cut off before you can mount the front bar. From the factory the front beam is spot welded and bolted in place. Depending upon the spot welding, you may have only a couple that can be easily broken by hand/pry bar, or, as in my case, it was nearly a full 1” bead weld above and below the frame mount that required both drilling and cutting to remove. An unexpected PITA.

All that to say, the rear tow beam was MUCH easier to install in my setup. The cutting of the bumper cover is more tedious than difficult. If you are not overly concerned about aesthetics it can be done quickly. I was very much concerned, so it took about two hours to get the holes just large enough for the female tow loop to pass through the plastic cover without a gap.

Brake ducts are a bit of a mix. I would certainly not say “bigger is always better.” I have many photos showing 302R/S race teams using bumper duct block off plates to keep some heat in the pads and rotors. The amount blocked off seems to be very track dependent. My car is used for occasional mountain road rallies (point-to-point) and a singular sprint event each year. Not road course racing. In my case the 302S/R 4” ducts are overkill and purely to add a piece of limited racing equipment to my car. They were not needed to address brake cooling issues. If anything, they often run too cool and I am working on blocking plates similar to the race teams. I also think the 302S ducts look better than the OEM 3” units.

Thank you for the questions, this is the motivation I need to put the steps and photos for both projects in my build thread

If more questions arise let me know. The tow beams can both be completed in a day. The ducts likely will require their own day depending upon your access to the underside. I have a lift so it only took a few hours.

Thanks for the detail on installation of the tubular pieces in place of the beams. The rear is going to make the winter project list, assuming Watson still has them in stack. For the front, I have a ZL1 Addon tow look. The offset from center is the negative, if I trailer the car a centered location would be preferred for a winch.@Boss4Me The rear bumper does not have a foam core support. It is simply plastic bumper cover and bolt-on rear beam. The DOT requires foam up front to meet pedestrian and low speed crash requirements. I scrapped my front foam before final mounting as it was more trouble than it was worth.

The front bumper beam is different. It has to be unbolted and cut off before you can mount the front bar. From the factory the front beam is spot welded and bolted in place. Depending upon the spot welding, you may have only a couple that can be easily broken by hand/pry bar, or, as in my case, it was nearly a full 1” bead weld above and below the frame mount that required both drilling and cutting to remove. An unexpected PITA.

All that to say, the rear tow beam was MUCH easier to install in my setup. The cutting of the bumper cover is more tedious than difficult. If you are not overly concerned about aesthetics it can be done quickly. I was very much concerned, so it took about two hours to get the holes just large enough for the female tow loop to pass through the plastic cover without a gap.

Brake ducts are a bit of a mix. I would certainly not say “bigger is always better.” I have many photos showing 302R/S race teams using bumper duct block off plates to keep some heat in the pads and rotors. The amount blocked off seems to be very track dependent. My car is used for occasional mountain road rallies (point-to-point) and a singular sprint event each year. Not road course racing. In my case the 302S/R 4” ducts are overkill and purely to add a piece of limited racing equipment to my car. They were not needed to address brake cooling issues. If anything, they often run too cool and I am working on blocking plates similar to the race teams. I also think the 302S ducts look better than the OEM 3” units.

Thank you for the questions, this is the motivation I need to put the steps and photos for both projects in my build thread

If more questions arise let me know. The tow beams can both be completed in a day. The ducts likely will require their own day depending upon your access to the underside. I have a lift so it only took a few hours.

For my ‘14 GT project, I went down the path of attempting to replicate the ‘13 LS brake duct adaptors. The CS fog light trim part was simple OE online catalog part (thanks for the tip from another TMO’er). The unobtainable part is the bent metal/welded piece that attaches to the back of that trim part. After a few calls, Capaldi supplied that part to Ford for the factory throw-in LS brake kit. I talked with Leo and he could not find any remaining pieces. So I just dremeled an opening the GT trim insert attached a 3” adaptor from Allstar and called it functional, ugly but functional.

For what it's worth, LMR seems to have begun selling what appears to be a direct copy of the Blowfish tow hook under the SVE name, minus the mount point for the plate holder, for the 10-14 cars.Mostly, yes. They still make the MT82 shifter support bracket in addition to selling some NOS items from previous production runs. They can be found as user mustang-madness on eBay. As far as the topic of this thread, though, their tow hook set ups are probably knocked off the list as a contender unless you can find one second-hand.

- 602

- 540

Yeah I made a thread about it when it came out. https://trackmustangsonline.com/threads/2005-2014-sve-front-towhook.20167/For what it's worth, LMR seems to have begun selling what appears to be a direct copy of the Blowfish tow hook under the SVE name, minus the mount point for the plate holder, for the 10-14 cars.

This was an older post with the options that were available at the time.

Ah my bad, must have missed it. Still going to try to track down a Blowfish, as I really like the option of the plate holder, but may go with the SVE if I'm unsuccessful.Yeah I made a thread about it when it came out. https://trackmustangsonline.com/threads/2005-2014-sve-front-towhook.20167/

This was an older post with the options that were available at the time.

The one on the forum marketplace still seems available....Still going to try to track down a Blowfish