- Welcome to the Ford Mustang forum built for owners of the Mustang GT350, BOSS 302, GT500, and all other S550, S197, SN95, Fox Body and older Mustangs set up for open track days, road racing, and/or autocross. Join our forum, interact with others, share your build, and help us strengthen this community!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Vorshlag 2018 Mustang GT + S550 Development Thread

- Thread starterFair

- Start date

This site may earn a commission from merchant affiliate links, including eBay, Amazon, and others.

More options

Who Replied?- Thread starter

- #62

Project Update for October 5th, 2018: Lots to cover since our last post. Due to customer obligations we did not have a chance to order parts and install these updates on our own S550 until the WEEK before NASA National Championships, so we did what say to never do - last minute updates with zero testing before a big event!

There were also delays due to the sequencing of production testing for some new parts we have been working with, like the Powerbrake 380x32mm rotor / 6 piston Motorsports front brake kit. At the same time we installed a different set of coilovers (MCS RR2) - and we have more sets to test next. We also developed a production S550 bolt-in 4-point roll bar, seat bracket for a Sparco Circuit II seat, installed a new Schroth 6-point harness, and threw on a set of 315mm Hoosier A7s. Most of that was only wrapped up the day before NASA Nats. Yikes!

But I was excited to get back to COTA - so let's dig into Round #3 of mods to our car, then cover NASA Nationals and the short list of updates after.

PROTOTYPE S550 POWERBRAKE 6 PISTON BBK

Brakes: for cars used on track, this is the most important system on the whole car. We started with the base model GT, which comes with CRAP 14" front brakes. We then spent some time testing and upgrading the brakes to the 15" PP fronts. Now we wanted to go further...

Left: Base model 14" front inverted hat brakes. Bad. Right: 15" 6 piston PP brakes were next

We have covered our extensive struggles with the base model inverted hat brakes. We wiped out brand new OEM front brake pads in just 8 laps, down to the backing plates. Then we tested two G-LOC compounds up front (R8 and R16). With aggressive driving I could still fade the front brakes in one lap. ONE. LAP. It was all the rotors' fault, so we upgraded to the Performance Pack 15" dia 6-piston brakes and new G-LOC pads. With 4" brake cooling, since that 15" rotor isn't made bass-akwards. Those worked much better. If I didn't know any better I would have thought this was "as good as it gets".

But I do know better. I've been spoiled with Motorsports level brakes on two of my own track cars for the previous 2 years. Our BMW 330Ci got a Powerbrake 340mm x 34mm 2-piece rotor and large 4 piston caliper front kit, shown above. I used the same set of front pads for 2 years - and they were still good for another year!

Our FR-S has the Powerbrake 325mm x 28mm 2-piece rotors and 4-piston caliper front kit. Still on the same pads 2 years later also. The difference in feel from the best OEM calipers to what these cars have is enormous. Side note: we did spend some time during the 3 month break between these S550 posts working on our FR-S, installing then track testing 315/30/18 Rival-S tires on 18x11" wheels with giant flares. #BigTiresMatter You can read about that in this linked build thread.

We knew before we even bought this 2018 Mustang that we wanted to help validate a new Powerbrake kit for the S550 chassis. We have worked with this company to develop and test 350mm 6-piston kits on SN95 & S197 Mustangs and C6 Corvettes, as well as our BMW and FR-S shown above. With the weight and power of this S550, Powerbrake wanted to use a larger 380 x 34mm 2-piece rotor kit to go with their X6EL 6-piston Motorsports caliper (shown above).

There are many benefits to upgrading from OEM brakes with 1-piece iron rotors to Motorsport bolted billet calipers and 2-piece rotors. Caliper rigidity with the thru-bolted construction stays stable with higher temperatures. Staggered bore, stainless, vented pistons can be designed to promote even pad wear (no tapering). The 2-piece floating rotor style prevents coning ("warping") as the iron rotor ring heats up, and the aluminum hat keeps weight down.

The weight difference can really add up. On our BMW E46, the weight drop for the front Powerbrake kit was 4 pounds, with a MASSIVE increase in caliper and rotor size. On our FR-S the PB kit it was 9 pounds lighter than stock, also with a substantial increase in both rotor and caliper sizes. On this S550 Mustang, the weight drop from the entire 15" PP brake package (14.26 lb loaded calipers + 34.12 lb rotor x 2 = 97 pounds) was 21 pounds going to the Powerbrake kit.

Left: 15" PP rotor = 34.12 lbs. Right: 380x34mm Powerbrake 2-piece rotor = 24.4 lbs

A good bit of this weight drop was in the rotors. The 14" inverted hat front rotor was 28.4 pounds and the 15" PP rotor was 34.12 pounds.

The rotor rings are replaceable, which saves costs in rack consumables down the road. This was us installing a replacement set of rotor rings going on Jamie Beck's ST2 Mustang that has 350mm Powerbrake 6 piston fronts - after a season and a half of racing!

After the PP master cylinder and booster upgrade, and with 4" of brake cooling forced inside the hat of the front rotors, the 15" OEM Performance Pack brakes worked admirably. But again - I had two other track cars at the time with Powerbrake BBKs, and I knew what that difference felt like. The data logged braking on the upgraded OEM 15" brakes was better than the base 14" brakes, just not stellar. Not what I'm used to anymore.

One week before NASA Nationals we installed this prototype Powerbrake big brake kit to our 2018 GT.

continued below

There were also delays due to the sequencing of production testing for some new parts we have been working with, like the Powerbrake 380x32mm rotor / 6 piston Motorsports front brake kit. At the same time we installed a different set of coilovers (MCS RR2) - and we have more sets to test next. We also developed a production S550 bolt-in 4-point roll bar, seat bracket for a Sparco Circuit II seat, installed a new Schroth 6-point harness, and threw on a set of 315mm Hoosier A7s. Most of that was only wrapped up the day before NASA Nats. Yikes!

But I was excited to get back to COTA - so let's dig into Round #3 of mods to our car, then cover NASA Nationals and the short list of updates after.

PROTOTYPE S550 POWERBRAKE 6 PISTON BBK

Brakes: for cars used on track, this is the most important system on the whole car. We started with the base model GT, which comes with CRAP 14" front brakes. We then spent some time testing and upgrading the brakes to the 15" PP fronts. Now we wanted to go further...

Left: Base model 14" front inverted hat brakes. Bad. Right: 15" 6 piston PP brakes were next

We have covered our extensive struggles with the base model inverted hat brakes. We wiped out brand new OEM front brake pads in just 8 laps, down to the backing plates. Then we tested two G-LOC compounds up front (R8 and R16). With aggressive driving I could still fade the front brakes in one lap. ONE. LAP. It was all the rotors' fault, so we upgraded to the Performance Pack 15" dia 6-piston brakes and new G-LOC pads. With 4" brake cooling, since that 15" rotor isn't made bass-akwards. Those worked much better. If I didn't know any better I would have thought this was "as good as it gets".

But I do know better. I've been spoiled with Motorsports level brakes on two of my own track cars for the previous 2 years. Our BMW 330Ci got a Powerbrake 340mm x 34mm 2-piece rotor and large 4 piston caliper front kit, shown above. I used the same set of front pads for 2 years - and they were still good for another year!

Our FR-S has the Powerbrake 325mm x 28mm 2-piece rotors and 4-piston caliper front kit. Still on the same pads 2 years later also. The difference in feel from the best OEM calipers to what these cars have is enormous. Side note: we did spend some time during the 3 month break between these S550 posts working on our FR-S, installing then track testing 315/30/18 Rival-S tires on 18x11" wheels with giant flares. #BigTiresMatter You can read about that in this linked build thread.

We knew before we even bought this 2018 Mustang that we wanted to help validate a new Powerbrake kit for the S550 chassis. We have worked with this company to develop and test 350mm 6-piston kits on SN95 & S197 Mustangs and C6 Corvettes, as well as our BMW and FR-S shown above. With the weight and power of this S550, Powerbrake wanted to use a larger 380 x 34mm 2-piece rotor kit to go with their X6EL 6-piston Motorsports caliper (shown above).

There are many benefits to upgrading from OEM brakes with 1-piece iron rotors to Motorsport bolted billet calipers and 2-piece rotors. Caliper rigidity with the thru-bolted construction stays stable with higher temperatures. Staggered bore, stainless, vented pistons can be designed to promote even pad wear (no tapering). The 2-piece floating rotor style prevents coning ("warping") as the iron rotor ring heats up, and the aluminum hat keeps weight down.

The weight difference can really add up. On our BMW E46, the weight drop for the front Powerbrake kit was 4 pounds, with a MASSIVE increase in caliper and rotor size. On our FR-S the PB kit it was 9 pounds lighter than stock, also with a substantial increase in both rotor and caliper sizes. On this S550 Mustang, the weight drop from the entire 15" PP brake package (14.26 lb loaded calipers + 34.12 lb rotor x 2 = 97 pounds) was 21 pounds going to the Powerbrake kit.

Left: 15" PP rotor = 34.12 lbs. Right: 380x34mm Powerbrake 2-piece rotor = 24.4 lbs

A good bit of this weight drop was in the rotors. The 14" inverted hat front rotor was 28.4 pounds and the 15" PP rotor was 34.12 pounds.

The rotor rings are replaceable, which saves costs in rack consumables down the road. This was us installing a replacement set of rotor rings going on Jamie Beck's ST2 Mustang that has 350mm Powerbrake 6 piston fronts - after a season and a half of racing!

After the PP master cylinder and booster upgrade, and with 4" of brake cooling forced inside the hat of the front rotors, the 15" OEM Performance Pack brakes worked admirably. But again - I had two other track cars at the time with Powerbrake BBKs, and I knew what that difference felt like. The data logged braking on the upgraded OEM 15" brakes was better than the base 14" brakes, just not stellar. Not what I'm used to anymore.

One week before NASA Nationals we installed this prototype Powerbrake big brake kit to our 2018 GT.

continued below

- Thread starter

- #63

continued from above

We had to make a custom front brake flex line, but we have shared that info with Powerbrake and it should be in the production S550 kit by the time you read this. We also trimmed up our prototype S550 front brake cooling backing plates, just slightly, so that this can now work with the 15" PP brakes or the 380mm Powerbrake kit.

After bleeding the system with fresh RBF600 Motul brake fluid I was eager to test these on track, but our compressed build schedule would not allow for a dedicated track test - we'd be testing at Nationals!

MCS RR2 SUSPENSION UPGRADE

We ran 7 of the first 8 events on the Whiteline monotube inverted coilovers. This was something they asked us to test, as we have a long history working with Whiteline. We had good results and ride quality but by the time we got them on the car and on our website for sale, the deal with their supplier went away, and we had to stop offering that setup. After that we ordered what we had originally intended to use for the long term with Hoosiers - these MCS Remote Doubles, which we call the RR2 model.

We paired these dampers with Vorshlag S550 camber plates, some of our prototype spherical rear shock mounts (more on that later), and one of 3 tested sets of Hyperco springs we spec'd for this application. The spring rates we chose are our "middle" set: 600 #/in F, 750 #/in R. We call this our "GTS" rates, with the GT rates being softer and GTR stiffer. We ran the softer GT rates (400 #/in) on the Whiteline set and still noted some body roll and dive, so we wanted to see the difference on the MCS set, which would only be amplified by the upgrade to stickier Hoosier A7 tires.

Unlike the inverted Whiteline and Ohlins kit for the S550 chassis, the front MCS strut is a traditional (non-inverted) 22mm shaft monotube with the Rebound knob at the top of the shaft and the Compression knob on the remote canister. The rear damper is in fact an inverted setup, also using a 22mm shaft monotube with the Rebound knob near the lower "T-bar" mount and the Compression knob on the remote. This was the first inverted rear MCS we had run in anger, and we have passed on a few suggestions that MCS has already incorporated into their S550 shock.

The installation was pretty straight forward, but as you can see the strut stem and knob would be pretty close to the edge of the strut tower opening - and in fact will limit camber travel. The Whiteline was an inverted front strut, which has a super short upper stem and the knob at the bottom, so that constraint wasn't an issue. The top mounted knob on the MCS makes for easier access, but the S550's small strut tower opening (only 1.8 inches - more on that below) made it to where we left the knob off for the COTA event (we ran out of time to modify the towers). I was able to make Rebound adjustments with the small Allen wrench supplied, using the holes in the upper hex portion of the adjuster.

These went on the car on a Wednesday, and we loaded up for our trip to NASA Nationals on Thursday night. To call this "rushed" would be an insult to the word "rush", hehe. No major issues noted in the two test drives I took in the car that day, rode fine and we set the knobs to about "halfway" on rebound and compression both.

S550 PRE-PRODUCTION 4-POINT ROLL BAR

Most folks know that we make roll cages. For a dedicated race car that's all I want to have protecting me anymore. Of course our 2018 GT is very much a dual-purpose street/track car. For that situation a 4-point roll bar makes for a safer setup on the street (no rooftop door bars near an un-helmeted head), yet still gives us some rollover protection and a GREAT place to hang some shoulder harnesses from, for use with a fixed back racing seat and 6-point harnesses. I have been really missing those safety items in this car.

In the past we have used the Maximum Motorsports 4-point roll bars kits for the S197 chassis, with some key options picked. But its no secret that I haven't been too happy with the bolt-in roll bar options available for the S550 Mustang chassis (and Maximum doesn't have one for the S550, as of this writing). We looked at 4 different options and found things we could improve on all of them. If it looked like we could improve on the options out there we agreed that it could be a new production part from Vorshlag.

We started by removing the front and rear seats and all of the rear interior panels. I wanted a "clean slate" to look for good factory bolt holes to key the roll bar off of. We also looked at NASA Club Codes & Regulations for material requirements, bar routing, angle suggestions, and other engineering aspects for W2W roll cages (that we applied to the "half cage" that we built).

After copious scraping of seam sealer from some key areas, Jason (engineer), Myles (new engineer/CNC guy), Evan (fabricator) and I all brain-stormed some ideas using the best methods of attachment we could find in the back of this chassis. I had a few requirements that I would not budge on: a fully welded assembly (no post-delivery welding!); a diagonal in the main hoop; use 1.75" x .120" wall DOM tubing (not drag race tube specs); the main hoop kept tight to the roof; and a recessed harness bar for use with taller drivers.

After some iterations in cardboard, I was happy with the landing plates for the main hoop and rear downbars (the "4 points" of this roll bar design). We transferred the cardboard templates into CAD files, then using our new CNC plasma table, cut out plate steel in two thicknesses over 4 revisions before we had the "base plates" and mounting plinths built to our liking.

Unlike the S197 chassis that has a replaceable corner section for the main hoop to land, we made these that bolt into the chassis and nest over top of the OEM bits here. This puts the main hoop at the optimum location for the tallest part of the roof, close (but not TOO close) to the driver, and as wide as possible.

continued below

We had to make a custom front brake flex line, but we have shared that info with Powerbrake and it should be in the production S550 kit by the time you read this. We also trimmed up our prototype S550 front brake cooling backing plates, just slightly, so that this can now work with the 15" PP brakes or the 380mm Powerbrake kit.

After bleeding the system with fresh RBF600 Motul brake fluid I was eager to test these on track, but our compressed build schedule would not allow for a dedicated track test - we'd be testing at Nationals!

MCS RR2 SUSPENSION UPGRADE

We ran 7 of the first 8 events on the Whiteline monotube inverted coilovers. This was something they asked us to test, as we have a long history working with Whiteline. We had good results and ride quality but by the time we got them on the car and on our website for sale, the deal with their supplier went away, and we had to stop offering that setup. After that we ordered what we had originally intended to use for the long term with Hoosiers - these MCS Remote Doubles, which we call the RR2 model.

We paired these dampers with Vorshlag S550 camber plates, some of our prototype spherical rear shock mounts (more on that later), and one of 3 tested sets of Hyperco springs we spec'd for this application. The spring rates we chose are our "middle" set: 600 #/in F, 750 #/in R. We call this our "GTS" rates, with the GT rates being softer and GTR stiffer. We ran the softer GT rates (400 #/in) on the Whiteline set and still noted some body roll and dive, so we wanted to see the difference on the MCS set, which would only be amplified by the upgrade to stickier Hoosier A7 tires.

Unlike the inverted Whiteline and Ohlins kit for the S550 chassis, the front MCS strut is a traditional (non-inverted) 22mm shaft monotube with the Rebound knob at the top of the shaft and the Compression knob on the remote canister. The rear damper is in fact an inverted setup, also using a 22mm shaft monotube with the Rebound knob near the lower "T-bar" mount and the Compression knob on the remote. This was the first inverted rear MCS we had run in anger, and we have passed on a few suggestions that MCS has already incorporated into their S550 shock.

The installation was pretty straight forward, but as you can see the strut stem and knob would be pretty close to the edge of the strut tower opening - and in fact will limit camber travel. The Whiteline was an inverted front strut, which has a super short upper stem and the knob at the bottom, so that constraint wasn't an issue. The top mounted knob on the MCS makes for easier access, but the S550's small strut tower opening (only 1.8 inches - more on that below) made it to where we left the knob off for the COTA event (we ran out of time to modify the towers). I was able to make Rebound adjustments with the small Allen wrench supplied, using the holes in the upper hex portion of the adjuster.

These went on the car on a Wednesday, and we loaded up for our trip to NASA Nationals on Thursday night. To call this "rushed" would be an insult to the word "rush", hehe. No major issues noted in the two test drives I took in the car that day, rode fine and we set the knobs to about "halfway" on rebound and compression both.

S550 PRE-PRODUCTION 4-POINT ROLL BAR

Most folks know that we make roll cages. For a dedicated race car that's all I want to have protecting me anymore. Of course our 2018 GT is very much a dual-purpose street/track car. For that situation a 4-point roll bar makes for a safer setup on the street (no rooftop door bars near an un-helmeted head), yet still gives us some rollover protection and a GREAT place to hang some shoulder harnesses from, for use with a fixed back racing seat and 6-point harnesses. I have been really missing those safety items in this car.

In the past we have used the Maximum Motorsports 4-point roll bars kits for the S197 chassis, with some key options picked. But its no secret that I haven't been too happy with the bolt-in roll bar options available for the S550 Mustang chassis (and Maximum doesn't have one for the S550, as of this writing). We looked at 4 different options and found things we could improve on all of them. If it looked like we could improve on the options out there we agreed that it could be a new production part from Vorshlag.

We started by removing the front and rear seats and all of the rear interior panels. I wanted a "clean slate" to look for good factory bolt holes to key the roll bar off of. We also looked at NASA Club Codes & Regulations for material requirements, bar routing, angle suggestions, and other engineering aspects for W2W roll cages (that we applied to the "half cage" that we built).

After copious scraping of seam sealer from some key areas, Jason (engineer), Myles (new engineer/CNC guy), Evan (fabricator) and I all brain-stormed some ideas using the best methods of attachment we could find in the back of this chassis. I had a few requirements that I would not budge on: a fully welded assembly (no post-delivery welding!); a diagonal in the main hoop; use 1.75" x .120" wall DOM tubing (not drag race tube specs); the main hoop kept tight to the roof; and a recessed harness bar for use with taller drivers.

After some iterations in cardboard, I was happy with the landing plates for the main hoop and rear downbars (the "4 points" of this roll bar design). We transferred the cardboard templates into CAD files, then using our new CNC plasma table, cut out plate steel in two thicknesses over 4 revisions before we had the "base plates" and mounting plinths built to our liking.

Unlike the S197 chassis that has a replaceable corner section for the main hoop to land, we made these that bolt into the chassis and nest over top of the OEM bits here. This puts the main hoop at the optimum location for the tallest part of the roof, close (but not TOO close) to the driver, and as wide as possible.

continued below

- Thread starter

- #64

continued from above

Once the main hoop was bent and trimmed it was fit snugly into the car (with the interior roof panel in place - it's touching). Then the diagonal, harness bar, and rear down bars were tack welded in. It was removed and final TIG welded. The main hoop was routed to clear the OEM shoulder harnesses, so a dual-purpose car (like this) can use the stock belts for street use. Much safer that way.

The completed roll bar was installed for the final time before we moved to other systems. It sits on the rear seat bulkhead and just rolls back onto the rear seat belt mounting studs and holes. Two holes are drilled in the chassis at the rear down bar mounts (4 bolts per plate) and we could have slipped in the rear interior panels and given them a trim, but I'm going to see about that soon.

No, there are no provisions to install the rear seats or seat belts. Why? Because that is silly - nobody should EVER ride in the back seat area with a 4-point roll bar installed inches from their face. As you can see 62 pounds of back seats, belts, hardware, and interior panels came out and about 58 pounds went in with the 4-point roll bar. A net loss of 4 pounds while adding some safety.

At least now I can have some place to mount shoulder harnesses, and feel safer in this car than before. We ran the bar in raw steel for COTA but pulled it out when we returned for powder coat. Next up in our last week thrash... adding a racing seat!

S550 PRE-PRODUCTION SEAT BRACKET + SPARCO SEAT + SCHROTH HARNESS

If you have read my posts on other build threads you might know how much we dislike most of the "bolt-in" seat bracket kits out there on the market. I've yet to see one that I really liked. They tend to be weak, sloppy/floppy, poorly fitting messes. I talk at length about seats and mounting challenges in this forum post.

The base "300A" interior GT 6-speed we got stickered for $36.6K retail. Of course the base seats are COMPLETE GARBAGE, and we thought about upgrading to the "$1595" Recaros. Those work fairly well and would be a great option - if they weren't $10K! Yes, go to the FORD website configurator or click the top right pic to see this: you have to upgrade a bunch of packages to be able to buy the "$1595" Recaro seats, which is how it becomes a $10,095 seat upgrade!

Remember back to my original post about why we purchased a base GT? We wanted to avoid a bunch of useless fluff that would be replaced with better parts in our quest to make the "GT3 RS" version of the S550 Mustang. For less than the "$10,095" price for Recaros, we can damn sure pay for some fixed back racing seats, real harnesses, and a roll bar - just like the GT3 RS has.

pics of the seat brackets we made - with production in mind - for the late model Audi R8

This time instead of fabricating the brackets one-off we wanted to make a production worthy unit, like we did in this Audi R8 V10 last year. For that car we made a 100% bolt-in seat bracket that fit the carbon tub of that chassis, had provisions for the lower 4-points of a 6-point harness, had a bracket to hold the OEM seat belt lower buckle, allowed for the use of a slider, and made the seat install easy.

That setup worked VERY well in this 2017 R8. Weirdly enough the car was wrecked HARD at COTA later that year, and our harness bar + seat brackets + harness mounts held up perfectly. Guy walked away without a scratch. #CrashTested

With our CNC plasma table we could make the S550 "production seat bracket" version 100% in-house. Problem was... the first two iterations didn't look clean as the Audi version we made. Super heavy duty. I mentioned what a time crunch we were in - #NASAchamps was just days away! We had to make this version work for the short term, even if it was a little ugly. Plenty strong and rigid, just not production ready.

The floor in the S550 has some funky angles, and we used too thick of a piece of steel on this iteration. The prototype worked well, even if a bit on the heavy side and time-consuming to weld up. I could fit my 6'3" frame inside with CRAZY room to the headliner, and the slider allows Amy to move forward as much as 18", so she can drive as well. I'm sitting at least 3" lower than stock. We will re-design this bracket and show the production version later in this build thread.

We used a single Sparco Circuit II seat with a full halo. Scroth's new for 2018 "FIA 2016" rated belts in red were chosen. We went with the 2" belts to make it easier for HANS use. The seat fits very well, slides back for taller drivers and forward for shorter, has no movement outside of the slider's own, and made for a much more comfortable "day at the office" pulling 1.5 g loading with 315mm Hoosier A7s!

ALIGNMENT, SCALES, & DYNO TESTING

We borrowed a friend's Hunter alignment rack and Evan aligned the car to get -3.5° front camber and -2.2° rear. We were in such a rush we didn't print a sheet.

continued below

Once the main hoop was bent and trimmed it was fit snugly into the car (with the interior roof panel in place - it's touching). Then the diagonal, harness bar, and rear down bars were tack welded in. It was removed and final TIG welded. The main hoop was routed to clear the OEM shoulder harnesses, so a dual-purpose car (like this) can use the stock belts for street use. Much safer that way.

The completed roll bar was installed for the final time before we moved to other systems. It sits on the rear seat bulkhead and just rolls back onto the rear seat belt mounting studs and holes. Two holes are drilled in the chassis at the rear down bar mounts (4 bolts per plate) and we could have slipped in the rear interior panels and given them a trim, but I'm going to see about that soon.

No, there are no provisions to install the rear seats or seat belts. Why? Because that is silly - nobody should EVER ride in the back seat area with a 4-point roll bar installed inches from their face. As you can see 62 pounds of back seats, belts, hardware, and interior panels came out and about 58 pounds went in with the 4-point roll bar. A net loss of 4 pounds while adding some safety.

At least now I can have some place to mount shoulder harnesses, and feel safer in this car than before. We ran the bar in raw steel for COTA but pulled it out when we returned for powder coat. Next up in our last week thrash... adding a racing seat!

S550 PRE-PRODUCTION SEAT BRACKET + SPARCO SEAT + SCHROTH HARNESS

If you have read my posts on other build threads you might know how much we dislike most of the "bolt-in" seat bracket kits out there on the market. I've yet to see one that I really liked. They tend to be weak, sloppy/floppy, poorly fitting messes. I talk at length about seats and mounting challenges in this forum post.

The base "300A" interior GT 6-speed we got stickered for $36.6K retail. Of course the base seats are COMPLETE GARBAGE, and we thought about upgrading to the "$1595" Recaros. Those work fairly well and would be a great option - if they weren't $10K! Yes, go to the FORD website configurator or click the top right pic to see this: you have to upgrade a bunch of packages to be able to buy the "$1595" Recaro seats, which is how it becomes a $10,095 seat upgrade!

Remember back to my original post about why we purchased a base GT? We wanted to avoid a bunch of useless fluff that would be replaced with better parts in our quest to make the "GT3 RS" version of the S550 Mustang. For less than the "$10,095" price for Recaros, we can damn sure pay for some fixed back racing seats, real harnesses, and a roll bar - just like the GT3 RS has.

pics of the seat brackets we made - with production in mind - for the late model Audi R8

This time instead of fabricating the brackets one-off we wanted to make a production worthy unit, like we did in this Audi R8 V10 last year. For that car we made a 100% bolt-in seat bracket that fit the carbon tub of that chassis, had provisions for the lower 4-points of a 6-point harness, had a bracket to hold the OEM seat belt lower buckle, allowed for the use of a slider, and made the seat install easy.

That setup worked VERY well in this 2017 R8. Weirdly enough the car was wrecked HARD at COTA later that year, and our harness bar + seat brackets + harness mounts held up perfectly. Guy walked away without a scratch. #CrashTested

With our CNC plasma table we could make the S550 "production seat bracket" version 100% in-house. Problem was... the first two iterations didn't look clean as the Audi version we made. Super heavy duty. I mentioned what a time crunch we were in - #NASAchamps was just days away! We had to make this version work for the short term, even if it was a little ugly. Plenty strong and rigid, just not production ready.

The floor in the S550 has some funky angles, and we used too thick of a piece of steel on this iteration. The prototype worked well, even if a bit on the heavy side and time-consuming to weld up. I could fit my 6'3" frame inside with CRAZY room to the headliner, and the slider allows Amy to move forward as much as 18", so she can drive as well. I'm sitting at least 3" lower than stock. We will re-design this bracket and show the production version later in this build thread.

We used a single Sparco Circuit II seat with a full halo. Scroth's new for 2018 "FIA 2016" rated belts in red were chosen. We went with the 2" belts to make it easier for HANS use. The seat fits very well, slides back for taller drivers and forward for shorter, has no movement outside of the slider's own, and made for a much more comfortable "day at the office" pulling 1.5 g loading with 315mm Hoosier A7s!

ALIGNMENT, SCALES, & DYNO TESTING

We borrowed a friend's Hunter alignment rack and Evan aligned the car to get -3.5° front camber and -2.2° rear. We were in such a rush we didn't print a sheet.

continued below

- Thread starter

- #65

continued from above

We weighed the car earlier that day, right as the seat and roll bar install were wrapped up. We didn't install the other seat because of time constraints, but needed a weight and a dyno to figure out if we would run in TT3 class, and if so how close to the power and weight limit. 3607 lbs with no driver, 3825 lbs with driver and 3/8ths of a tank. We would always run the car full of fuel, which would add +50 lbs, even after some laps of fuel burn.

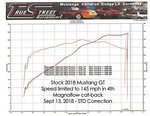

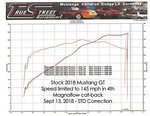

I was able to get into the busy schedule for a handful of dyno pulls at True Street Motorsports the day we were loading up. Richie made 5 pulls and he noted quickly that the car was hitting a 145mph speed limiter, due to the lower speed rated base model tires our car came equipped with. We had never hit 145mph on track (I just touched that speed at COTA in May, on the back straight) so I didn't know this existed. NASA rules require that the dyno tests are done in 4th gear, which on the 2018 GT's "MT82-D4" transmission is now 4th (from 2011-2017, 5th was 1:1).

That's why the dyno stop at 6750 rpm in 4th, due to the speed limit. Without re-programming the stock tune, it was what it was. We double checked the NASA dyno procedures and we decided to stick with this, as this is how the car could be dyno'd at Nationals (and they DO dyno a lot of cars there).

Dyno certification form, Dyno avg whp form, NASA TT classing sheet

With peaks of 443 whp STD / 435 whp SAE, using the NASA average dyno procedure calculates to 417 whp average. I ran the numbers, filled in our TT classing sheets, then ran the numbers again. We were safe for TT3 at 3825 lbs and 417 whp, but only just. To compensate for any scale mistakes or dyno errors, we claimed 423 whp avg (+6 whp) and 3855 lbs (+30 pounds). This comes out to 9.11:1 pounds per whp, and with our modifiers (+0.4 for stock aero and +0.5 for 3801-3900 pound race weight) we came to 10.01:1, p-to-w. We ran even heavier, crossing the scales after every session at 3860-3876 lbs at Nats.

We ran out of time to have the 315/30/19 Hoosier A7 tires mounted to our only set of 19x11" wheels (for now). So we tossed them in the trailer and hauled ass down to Austin Friday morning, hoping to get unloaded and on track by 4:45 pm that afternoon. We would play it by ear with the weather, possibly running some of the first sessions on the RE-71R street tires... because it was raining. HARD. And the forecast showed much of the same.

NASA @ COTA - May 2018 Recap

As a quick refresher, back in May we ran our 2018 GT at COTA with NASA. We did that event on the Whiteline coilovers, RE-71R tires, 15" PP brakes, and the track limits for that event were quite open (the large F1 curbs on the outside of T11, T12, T15, and T20 were missing). I ran a best lap of 2:32.9, which I was fairly happy with. That took 3rd place in TT3 class at this Regional TT event, losing to Paul Costas in the G-SPEED prepped C5 Corvette by a massive 10 seconds.

As crazy as that sounds, the 2:32 lap time was actually pretty good, and would have been the P2 qualifier in the American Iron W2W race field (AI times are something I've always compared our Mustang TT3 times to, as they are all pony cars with similar 9:1 power to weight ratios, full aero, etc). We saw high oil temp problems, traffic/tourist issues, and the street tires were holding the times back a bit, but I finally had brakes that worked - where I saw 1.2g braking into T1 and 1.0g into T12 (after back straight). Cornering was 1.1-1.25g lateral on the 200 treadwear tires.

NASA NATIONALS AT COTA, SEPT 14-16, 2018

After loading the Donkey and the Mustang into the trailer, Amy and I blasted down to COTA on Friday morning. We got there around 12 noon but the off site registration had closed, so we wandered into the "A" lot out front. The weather had been bad all week during testing and not many dry laps had been taken until that Friday morning. We didn't pay ~$1M for Thursday or Friday test and tune sessions, and instead would rely on the 5 or 6 TT sessions to setup and learn the new suspension/tires/brakes, running Friday night through Sunday.

Parking was a bit of a thing, with 500+ racers and 70 in Time Trial. The garages sold out ages ago at $2000/per, and even the lower paddock lot was full. So we parked out front in Lot A, near the kart track, outside of the track.

the distance to the paddock / grid area from Lot A was over a mile and a half, but luckily we had brought the Donkey - our recently restored Taylor Dunn pit vehicle. We drove many, many miles over this 3 day race weekend in the Donkey, staying dry in the rain and honking at everything that moved. Hauling fuel jugs and tires or taking passengers. A donkey is not known for its speed, but it sure beat walking!

Friday

With zero testing I was to go on track at 4:45 pm for the TT Warm Up. Raining pretty good, on the street tires. As I drive to grid I realize we have the rear ride height set too low and it's bottoming badly in paddock. Went out anyway, trying to move up from my 64th spot on the 70 car TT grid (they gridded us for the first session based on when we signed up?!) Passed over 20 cars in 3 very wet laps. Car bottomed out a lot, ran a 3:00 lap... terrible.

That night we had some major changes to make. In the dark. And rain. Forgot to bring a good floor jack and nobody around us had one, so we went to a local Harbor Freight and yelled "Sell me your finest jack, good sirs!" Got back, raised the ride height a little at a time until we got about an inch and a half of rear bump travel. Big thanks to competitor Paul Costas who helped us with these ride height changes! Drove each iteration around the very bumpy paddock roads and it was not perfect, but better.

Got back, raised the ride height a little at a time until we got about an inch and a half of rear bump travel. Big thanks to competitor Paul Costas who helped us with these ride height changes! Drove each iteration around the very bumpy paddock roads and it was not perfect, but better.

Snatched the wheels off, took them using the Donkey over to Hoosier, who said they would change them first thing in the morning at 7:30 First in line.

Saturday

We showed up early at Hoosier (7:15), nobody around. Came back at 7:45, and now we were 5th in line. Another TT meeting at 8:30, then on track at 10:10. We were waiting impatiently at Hoosier and they had all 4 tires mounted and balanced by 9:40. Hauled back to Lot A and went to mount the wheels and tires. "Only 10mm wider" than the 305mm tires we had on there? Should be no problem.

continued below

We weighed the car earlier that day, right as the seat and roll bar install were wrapped up. We didn't install the other seat because of time constraints, but needed a weight and a dyno to figure out if we would run in TT3 class, and if so how close to the power and weight limit. 3607 lbs with no driver, 3825 lbs with driver and 3/8ths of a tank. We would always run the car full of fuel, which would add +50 lbs, even after some laps of fuel burn.

I was able to get into the busy schedule for a handful of dyno pulls at True Street Motorsports the day we were loading up. Richie made 5 pulls and he noted quickly that the car was hitting a 145mph speed limiter, due to the lower speed rated base model tires our car came equipped with. We had never hit 145mph on track (I just touched that speed at COTA in May, on the back straight) so I didn't know this existed. NASA rules require that the dyno tests are done in 4th gear, which on the 2018 GT's "MT82-D4" transmission is now 4th (from 2011-2017, 5th was 1:1).

That's why the dyno stop at 6750 rpm in 4th, due to the speed limit. Without re-programming the stock tune, it was what it was. We double checked the NASA dyno procedures and we decided to stick with this, as this is how the car could be dyno'd at Nationals (and they DO dyno a lot of cars there).

Dyno certification form, Dyno avg whp form, NASA TT classing sheet

With peaks of 443 whp STD / 435 whp SAE, using the NASA average dyno procedure calculates to 417 whp average. I ran the numbers, filled in our TT classing sheets, then ran the numbers again. We were safe for TT3 at 3825 lbs and 417 whp, but only just. To compensate for any scale mistakes or dyno errors, we claimed 423 whp avg (+6 whp) and 3855 lbs (+30 pounds). This comes out to 9.11:1 pounds per whp, and with our modifiers (+0.4 for stock aero and +0.5 for 3801-3900 pound race weight) we came to 10.01:1, p-to-w. We ran even heavier, crossing the scales after every session at 3860-3876 lbs at Nats.

We ran out of time to have the 315/30/19 Hoosier A7 tires mounted to our only set of 19x11" wheels (for now). So we tossed them in the trailer and hauled ass down to Austin Friday morning, hoping to get unloaded and on track by 4:45 pm that afternoon. We would play it by ear with the weather, possibly running some of the first sessions on the RE-71R street tires... because it was raining. HARD. And the forecast showed much of the same.

NASA @ COTA - May 2018 Recap

As a quick refresher, back in May we ran our 2018 GT at COTA with NASA. We did that event on the Whiteline coilovers, RE-71R tires, 15" PP brakes, and the track limits for that event were quite open (the large F1 curbs on the outside of T11, T12, T15, and T20 were missing). I ran a best lap of 2:32.9, which I was fairly happy with. That took 3rd place in TT3 class at this Regional TT event, losing to Paul Costas in the G-SPEED prepped C5 Corvette by a massive 10 seconds.

As crazy as that sounds, the 2:32 lap time was actually pretty good, and would have been the P2 qualifier in the American Iron W2W race field (AI times are something I've always compared our Mustang TT3 times to, as they are all pony cars with similar 9:1 power to weight ratios, full aero, etc). We saw high oil temp problems, traffic/tourist issues, and the street tires were holding the times back a bit, but I finally had brakes that worked - where I saw 1.2g braking into T1 and 1.0g into T12 (after back straight). Cornering was 1.1-1.25g lateral on the 200 treadwear tires.

NASA NATIONALS AT COTA, SEPT 14-16, 2018

After loading the Donkey and the Mustang into the trailer, Amy and I blasted down to COTA on Friday morning. We got there around 12 noon but the off site registration had closed, so we wandered into the "A" lot out front. The weather had been bad all week during testing and not many dry laps had been taken until that Friday morning. We didn't pay ~$1M for Thursday or Friday test and tune sessions, and instead would rely on the 5 or 6 TT sessions to setup and learn the new suspension/tires/brakes, running Friday night through Sunday.

Parking was a bit of a thing, with 500+ racers and 70 in Time Trial. The garages sold out ages ago at $2000/per, and even the lower paddock lot was full. So we parked out front in Lot A, near the kart track, outside of the track.

the distance to the paddock / grid area from Lot A was over a mile and a half, but luckily we had brought the Donkey - our recently restored Taylor Dunn pit vehicle. We drove many, many miles over this 3 day race weekend in the Donkey, staying dry in the rain and honking at everything that moved. Hauling fuel jugs and tires or taking passengers. A donkey is not known for its speed, but it sure beat walking!

Friday

With zero testing I was to go on track at 4:45 pm for the TT Warm Up. Raining pretty good, on the street tires. As I drive to grid I realize we have the rear ride height set too low and it's bottoming badly in paddock. Went out anyway, trying to move up from my 64th spot on the 70 car TT grid (they gridded us for the first session based on when we signed up?!) Passed over 20 cars in 3 very wet laps. Car bottomed out a lot, ran a 3:00 lap... terrible.

That night we had some major changes to make. In the dark. And rain. Forgot to bring a good floor jack and nobody around us had one, so we went to a local Harbor Freight and yelled "Sell me your finest jack, good sirs!"

Snatched the wheels off, took them using the Donkey over to Hoosier, who said they would change them first thing in the morning at 7:30 First in line.

Saturday

We showed up early at Hoosier (7:15), nobody around. Came back at 7:45, and now we were 5th in line. Another TT meeting at 8:30, then on track at 10:10. We were waiting impatiently at Hoosier and they had all 4 tires mounted and balanced by 9:40. Hauled back to Lot A and went to mount the wheels and tires. "Only 10mm wider" than the 305mm tires we had on there? Should be no problem.

continued below

- Thread starter

- #66

continued from above

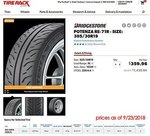

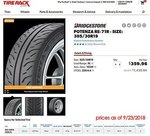

Big problems. Tires won't even turn, hard stop against struts in front and e-brake cables out back. These 19" Hoosiers are fully 1" wider per corner. YUGE! You can see that in the stack of 4 Hoosiers vs 4 Bridgestone tires, below left. We had to do a mad scramble and add some random 3/8" and 1/2" spacers behind all 4 wheels, which was all I had in the trailer.

Battery powered impact dies on the 7th wheel change, so we're spinning these lug nuts onto super long ARP studs by hand. We had NO TIME left. I jump into the car (sans driving suit), drive over to paddock, and make it at the 5 minute warning, when they are about to close grid. CLOSE!

I managed a decent first session, ran a 2:37.339 lap on a moist track, only a tenth behind Costas. Good time, moved me WAY up the grid.

2nd session was pissing rain as we went out, I was 24th on the grid, but I went out on the A7s anyway. then I passed everyone ahead of me. I had a blast - this was my favorite session on track of the weekend. Had a 2:51.0 best wet lap. I love racing in the rain, as its when I have always done my best in autocross and track driving. No tread on these A7 tires, but it was still 10 seconds faster than the street tires on Friday. Won't bother bringing street tires as "emergency backup" rain tires ever again. Either bring Full Wets or don't bother.

3rd Saturday session was finally not wet - our first dry session of the weekend, and I ran my best so far. I put down a 2:30.333 lap, which was 11th quickest of the entire 70 car TT field. I was finally quicker than we ran in May here on street tires (*which had radically different track-out on 4 corners). That moved me up into 3rd place out of 10 in TT3 by then. Costas in the G-SPEED C5 ran a 2:24.948, provisionally had 1st in class, but his time was DSQd (blew dyno). Schotz was quick and really in 1st with a 2:27.559. Our customer Adam B in his EVO X (we had done a lot of safety work to thisd car) was ahead of me in 2nd by 0.05 sec with a 2:30.293. We were all bunched up, other than Costas, but he had dyno problems...

At this point I felt pretty good about our performance, so we left the car alone and went to dinner at Javi's with Adam and also Danny Puskar from G-LOC brakes - where he had his first ever taste of Mexican food. Like... ever!

Sunday

Sunday the Championship races were wrapped or wrapping up for the W2W classes. TT had 2 more sessions that counted, but those were each in a "split group" with the faster half of the TT grid in the A group then the slower half of the field in the B. Less traffic with half as many cars on track, and by this point the field had pretty much sorted itself out by times / placement. It was much easier to get clear track this way.

After our 7:15 am TT meeting, I went out in the 8:20 am A group TT session, where it was 77°F, overcast, and dry - our second dry session of the weekend. I spent Lap 1 behind Adam's EVO and and put down a 2:28.980 lap (shown in the video above). Adam started pulling away from me on lap two but I slowed down a half second; he ran his 2:28.4 best. In the B group some TT3 BMW threw down a 2:27 and jumped up to 3rd place, outta nowhere... so I fell to 5th and Adam to 4th.

The next session was dry but considerably warmer, and almost everyone slowed by about a second. The "golden session" was that Sunday morning early one. That's when 95% of the TT racers put in their best time.

My 5th place time in TT3 would have been 3rd place in TT1 or TTU, faster classes that just had a little less depth in the field. Oh well.

Podium pics from TT - congrats to all trophy winners!

We went to the award ceremony and congratulated everyone who got a trophy. I don't think any TT records fell - again, everyone was faster back in May. We packed up our paddock spot, loaded the Donkey and the Mustang into the trailer, got on the road by 3:30 pm and were home by 8 pm.

Results Analysis, Issues, and Lessons Learned

Driving in the rain on A7s isn't terrible, unless it is POURING rain. A pit vehicle with a covered top is highly desired at wet events! #TheDonkeyRules

Oil temps were a real problem all weekend, even more than we have seen before. In the wet I could do 4-5 laps before oil temps got into the red and the car went into limp mode. In the dry sessions it was rare the car could go beyond 2 hot laps. I was taking precautions and not letting the car idle in grid, taking a super tame out lap, and only giving it full throttle and rpms on the hot laps. We have already ordered a new radiator and oil cooler, plus a suite of analog gauges (see below) to fix this.

The Powerbrake setup was phenomenal all weekend. Super easy to push the car in the wet or dry. Best aspect of the car, even slightly better than forward acceleration, which this motor provides plenty of. Coupled with Hoosier A7s there are several 1.4-1.5 g stops into T1, and 1.2-1.3g into T12. Lateral grip was 1.3-1.4g when I loaded the car up in corners.

Forward acceleration was a little hampered here by the unusual trans+rear gearing - I was never quite in the right gear. 2nd was a bit much and could easily haze the rear tires out of T20 and T11. 3rd was a hair sluggish in some corners. Didn't top out 4th on the massive back straight (touching 146 mph), which is the 1:1 gear, at our fastest track on the calendar?! This MT82-D4 gearing is wacky and we will obviously change the rear gears to a 3.73 or 4.09 final drive soon. We will run the calcs for the tire heights we use and pick the best ratio and re-gear.

The rear suspension was bottoming out in 4-5 corners per lap, even after the ride height changes made Friday night. So I had to drive around apexes and avoid some of the bumpiest sections - that cost me some time. And of course the track-out on T11, T12, T14, and T20 were massively different from the May NASA event, which easily cost us 2-3 sec per lap (most racers that ran both events noted this delta). We could still track out of T19 as much as we wanted, which I always did...

video of tracking me out of T19 behind Costas... maybe that was a bit much, LOL!

Traffic was pretty ugly for the first few wet sessions, as some of the slower drivers in faster classes held up cars behind them. This TT1 classed Audi was particularly bad about blocking, and held me up on no fewer than 3 sessions. Driver was just not aware of anyone around him, at all, and dozens of us complained about him and a few others in the driver's meetings. This sometimes happens at Regional events, but to see drivers with so little situational awareness at a National Championship was odd. Some drivers very nearly got an event DSQ from this stuff.

I like the fact that National TT Czar Greg G. held 5 separate TT driver's meetings. It let us give feedback on issues like these blockers, rules situations, flag infractions, and dyno questions. I liked the meeting frequency. Very much favor of this format rather than the "one meeting for the weekend" format most NASA regions run. There were probably 10 people that got session DSQs from our feedback in these 5 meetings - all of which were well deserved. Greg always took roll, so if you missed a meeting and didn't send an approved proxy - you also got a DSQ from the previous and/or next session.

continued below

Big problems. Tires won't even turn, hard stop against struts in front and e-brake cables out back. These 19" Hoosiers are fully 1" wider per corner. YUGE! You can see that in the stack of 4 Hoosiers vs 4 Bridgestone tires, below left. We had to do a mad scramble and add some random 3/8" and 1/2" spacers behind all 4 wheels, which was all I had in the trailer.

Battery powered impact dies on the 7th wheel change, so we're spinning these lug nuts onto super long ARP studs by hand. We had NO TIME left. I jump into the car (sans driving suit), drive over to paddock, and make it at the 5 minute warning, when they are about to close grid. CLOSE!

I managed a decent first session, ran a 2:37.339 lap on a moist track, only a tenth behind Costas. Good time, moved me WAY up the grid.

2nd session was pissing rain as we went out, I was 24th on the grid, but I went out on the A7s anyway. then I passed everyone ahead of me. I had a blast - this was my favorite session on track of the weekend. Had a 2:51.0 best wet lap. I love racing in the rain, as its when I have always done my best in autocross and track driving. No tread on these A7 tires, but it was still 10 seconds faster than the street tires on Friday. Won't bother bringing street tires as "emergency backup" rain tires ever again. Either bring Full Wets or don't bother.

3rd Saturday session was finally not wet - our first dry session of the weekend, and I ran my best so far. I put down a 2:30.333 lap, which was 11th quickest of the entire 70 car TT field. I was finally quicker than we ran in May here on street tires (*which had radically different track-out on 4 corners). That moved me up into 3rd place out of 10 in TT3 by then. Costas in the G-SPEED C5 ran a 2:24.948, provisionally had 1st in class, but his time was DSQd (blew dyno). Schotz was quick and really in 1st with a 2:27.559. Our customer Adam B in his EVO X (we had done a lot of safety work to thisd car) was ahead of me in 2nd by 0.05 sec with a 2:30.293. We were all bunched up, other than Costas, but he had dyno problems...

At this point I felt pretty good about our performance, so we left the car alone and went to dinner at Javi's with Adam and also Danny Puskar from G-LOC brakes - where he had his first ever taste of Mexican food. Like... ever!

Sunday

Sunday the Championship races were wrapped or wrapping up for the W2W classes. TT had 2 more sessions that counted, but those were each in a "split group" with the faster half of the TT grid in the A group then the slower half of the field in the B. Less traffic with half as many cars on track, and by this point the field had pretty much sorted itself out by times / placement. It was much easier to get clear track this way.

After our 7:15 am TT meeting, I went out in the 8:20 am A group TT session, where it was 77°F, overcast, and dry - our second dry session of the weekend. I spent Lap 1 behind Adam's EVO and and put down a 2:28.980 lap (shown in the video above). Adam started pulling away from me on lap two but I slowed down a half second; he ran his 2:28.4 best. In the B group some TT3 BMW threw down a 2:27 and jumped up to 3rd place, outta nowhere... so I fell to 5th and Adam to 4th.

The next session was dry but considerably warmer, and almost everyone slowed by about a second. The "golden session" was that Sunday morning early one. That's when 95% of the TT racers put in their best time.

My 5th place time in TT3 would have been 3rd place in TT1 or TTU, faster classes that just had a little less depth in the field. Oh well.

Podium pics from TT - congrats to all trophy winners!

We went to the award ceremony and congratulated everyone who got a trophy. I don't think any TT records fell - again, everyone was faster back in May. We packed up our paddock spot, loaded the Donkey and the Mustang into the trailer, got on the road by 3:30 pm and were home by 8 pm.

Results Analysis, Issues, and Lessons Learned

Driving in the rain on A7s isn't terrible, unless it is POURING rain. A pit vehicle with a covered top is highly desired at wet events! #TheDonkeyRules

Oil temps were a real problem all weekend, even more than we have seen before. In the wet I could do 4-5 laps before oil temps got into the red and the car went into limp mode. In the dry sessions it was rare the car could go beyond 2 hot laps. I was taking precautions and not letting the car idle in grid, taking a super tame out lap, and only giving it full throttle and rpms on the hot laps. We have already ordered a new radiator and oil cooler, plus a suite of analog gauges (see below) to fix this.

The Powerbrake setup was phenomenal all weekend. Super easy to push the car in the wet or dry. Best aspect of the car, even slightly better than forward acceleration, which this motor provides plenty of. Coupled with Hoosier A7s there are several 1.4-1.5 g stops into T1, and 1.2-1.3g into T12. Lateral grip was 1.3-1.4g when I loaded the car up in corners.

Forward acceleration was a little hampered here by the unusual trans+rear gearing - I was never quite in the right gear. 2nd was a bit much and could easily haze the rear tires out of T20 and T11. 3rd was a hair sluggish in some corners. Didn't top out 4th on the massive back straight (touching 146 mph), which is the 1:1 gear, at our fastest track on the calendar?! This MT82-D4 gearing is wacky and we will obviously change the rear gears to a 3.73 or 4.09 final drive soon. We will run the calcs for the tire heights we use and pick the best ratio and re-gear.

The rear suspension was bottoming out in 4-5 corners per lap, even after the ride height changes made Friday night. So I had to drive around apexes and avoid some of the bumpiest sections - that cost me some time. And of course the track-out on T11, T12, T14, and T20 were massively different from the May NASA event, which easily cost us 2-3 sec per lap (most racers that ran both events noted this delta). We could still track out of T19 as much as we wanted, which I always did...

video of tracking me out of T19 behind Costas... maybe that was a bit much, LOL!

Traffic was pretty ugly for the first few wet sessions, as some of the slower drivers in faster classes held up cars behind them. This TT1 classed Audi was particularly bad about blocking, and held me up on no fewer than 3 sessions. Driver was just not aware of anyone around him, at all, and dozens of us complained about him and a few others in the driver's meetings. This sometimes happens at Regional events, but to see drivers with so little situational awareness at a National Championship was odd. Some drivers very nearly got an event DSQ from this stuff.

I like the fact that National TT Czar Greg G. held 5 separate TT driver's meetings. It let us give feedback on issues like these blockers, rules situations, flag infractions, and dyno questions. I liked the meeting frequency. Very much favor of this format rather than the "one meeting for the weekend" format most NASA regions run. There were probably 10 people that got session DSQs from our feedback in these 5 meetings - all of which were well deserved. Greg always took roll, so if you missed a meeting and didn't send an approved proxy - you also got a DSQ from the previous and/or next session.

continued below

- Thread starter

- #67

continued from above

The National TT rule of "no passing on the first hot lap without a point by" was a little strange, but we got used to it. Some folks had trouble with the dyno but we weren't fast enough to get called up, so it didn't effect us. There were two scales and we were weighed after every session. I had issues on the left scale twice. It read my car 200 pounds light once, 100 pounds light another time. On the right side scale it was always 3860 - 3876 lbs, depending on fuel load, which was on the money. We learned a long time ago to only run this car at a FULL tank, which helped with ballast as well as prevented fuel starvation on left turns. With Hoosiers this was more important than ever.

My first lap was usually the quickest, as tires would get just a tick slower after one lap (normal for A7s). Obviously the 12" wide "315mm" Hoosiers didn't fit the car as we had it setup, and we had to scramble to make it work. You can see that clearly in the "as measured" tread width and section width numbers below for the RE-71R and A7. We've since fixed the spacer/camber issue (will show later in the thread) but I should have invested in another set of (18x11) wheels long ago, and test fit the Hoosiers at the shop (note that the 18" version of the 315mm A7 is $86/tire cheaper than the 19", below). There is a way to fit these 12" wide tires without spacers, but not without a lift and power tools. We have two more sets of race wheels ordered now (MOMO).

Of course setting up a car with all new EVERYTHING at a National Championship race weekend is the WRONG WAY TO DO THIS. Again, customer obligations forced my time table back to the 11th hour. Which meant I was still learning and tweaking the new setup in the handful of dry sessions we had that weekend, but still managed to close the gap to the #CheateringestCheaterBuggy C5 ;-) by 5 seconds, down from a 10 second gap from our last match-up in May.

The C5 that won TT3 was 2650 pounds (2880 with driver and ballast) and made about 288 whp (tuned down from 480 whp) with a custom "flat power" tune. Costas was often the quickest car on grid, and he put down some damned fast laps. G-SPEED had done some major improvements (Penskes, Brembo Motorsport brakes, rear diffuser, moved up to 335/345 A7s, new motor, magnesium C7Z06 subframe, and more) to this Corvette, dedicated testing and data collection at COTA, and we still caught up 5 seconds to their times. G-SPEED had the motor for this and the TTU winner built by HPR (which I am a small part of) and Costas is a good friend of mine, so I was happy for them.

That 5 second catch-up to Costas was my stretch goal for this event, and we managed to do that as well as outpace the entire American Iron grid (the fastest AI racers ran high 2:29s); they were the closest cars to our Pony car, at this event.

American Iron Champ Race results lap times

At one point our Mustang was 10th quickest on grid out of 70 in TT, in what I am fairly certain was the heaviest car on track, and one of only a handful of street cars around.

It was a VERY busy weekend here, as we had a crowd at our trailer at almost all times (customers, dealers, vendors), plus we had to park 1.5 miles away from grid, so there was significant time spent going back and forth to drive and for meetings. Next year we will register early and get a GARAGE in the front straight paddock - damn the $2000 cost! I missed just about every W2W race I wanted to watch, being stuck out in lot A.

Adam Baltutis in his TT3 EVO X (at left) and me throwing silly "VM" gang signs in front of our Fat Bastard! (on the right)

The new seat and harnesses worked GREAT! Wish we could have done this sooner. Even with higher g loading my back and arms weren't on fire, like they normally are after a long TT weekend. I wore my race suit in every session except one (where I barely made it to grid, jacking with the Hoosiers). It was hot and humid most of the weekend and I definitely got hot in my suit, so we need to seriously think about a cool suit (note the hoses coming out of Adam's suit, above - we added a cool suit setup to his car). If we add more power we will need the ballast anyway.

continued below

The National TT rule of "no passing on the first hot lap without a point by" was a little strange, but we got used to it. Some folks had trouble with the dyno but we weren't fast enough to get called up, so it didn't effect us. There were two scales and we were weighed after every session. I had issues on the left scale twice. It read my car 200 pounds light once, 100 pounds light another time. On the right side scale it was always 3860 - 3876 lbs, depending on fuel load, which was on the money. We learned a long time ago to only run this car at a FULL tank, which helped with ballast as well as prevented fuel starvation on left turns. With Hoosiers this was more important than ever.

My first lap was usually the quickest, as tires would get just a tick slower after one lap (normal for A7s). Obviously the 12" wide "315mm" Hoosiers didn't fit the car as we had it setup, and we had to scramble to make it work. You can see that clearly in the "as measured" tread width and section width numbers below for the RE-71R and A7. We've since fixed the spacer/camber issue (will show later in the thread) but I should have invested in another set of (18x11) wheels long ago, and test fit the Hoosiers at the shop (note that the 18" version of the 315mm A7 is $86/tire cheaper than the 19", below). There is a way to fit these 12" wide tires without spacers, but not without a lift and power tools. We have two more sets of race wheels ordered now (MOMO).

Of course setting up a car with all new EVERYTHING at a National Championship race weekend is the WRONG WAY TO DO THIS. Again, customer obligations forced my time table back to the 11th hour. Which meant I was still learning and tweaking the new setup in the handful of dry sessions we had that weekend, but still managed to close the gap to the #CheateringestCheaterBuggy C5 ;-) by 5 seconds, down from a 10 second gap from our last match-up in May.

The C5 that won TT3 was 2650 pounds (2880 with driver and ballast) and made about 288 whp (tuned down from 480 whp) with a custom "flat power" tune. Costas was often the quickest car on grid, and he put down some damned fast laps. G-SPEED had done some major improvements (Penskes, Brembo Motorsport brakes, rear diffuser, moved up to 335/345 A7s, new motor, magnesium C7Z06 subframe, and more) to this Corvette, dedicated testing and data collection at COTA, and we still caught up 5 seconds to their times. G-SPEED had the motor for this and the TTU winner built by HPR (which I am a small part of) and Costas is a good friend of mine, so I was happy for them.

That 5 second catch-up to Costas was my stretch goal for this event, and we managed to do that as well as outpace the entire American Iron grid (the fastest AI racers ran high 2:29s); they were the closest cars to our Pony car, at this event.

American Iron Champ Race results lap times

At one point our Mustang was 10th quickest on grid out of 70 in TT, in what I am fairly certain was the heaviest car on track, and one of only a handful of street cars around.

It was a VERY busy weekend here, as we had a crowd at our trailer at almost all times (customers, dealers, vendors), plus we had to park 1.5 miles away from grid, so there was significant time spent going back and forth to drive and for meetings. Next year we will register early and get a GARAGE in the front straight paddock - damn the $2000 cost! I missed just about every W2W race I wanted to watch, being stuck out in lot A.

Adam Baltutis in his TT3 EVO X (at left) and me throwing silly "VM" gang signs in front of our Fat Bastard! (on the right)

The new seat and harnesses worked GREAT! Wish we could have done this sooner. Even with higher g loading my back and arms weren't on fire, like they normally are after a long TT weekend. I wore my race suit in every session except one (where I barely made it to grid, jacking with the Hoosiers). It was hot and humid most of the weekend and I definitely got hot in my suit, so we need to seriously think about a cool suit (note the hoses coming out of Adam's suit, above - we added a cool suit setup to his car). If we add more power we will need the ballast anyway.

continued below

- Thread starter

- #68

continued from above

Amy was my rock over the 3 day Nationals weekend - she could have driven on Team Vorshlag but due to the limited number of dry sessions she let me drive them all. She kept me hydrated and fed between sessions, helped with tire changes, took pictures, everything. The weather was a constant challenge but everyone had to deal with it, and we got our two dry TT sessions. There was a little drama, and a car that was handicapped a bit (oil temps & rear shocks), but I was damn happy to run a 2:28 lap in a heavy car, with a bone stock engine, AC, zero aero, and that was still street legal. I used the AC on many occasions!

We had a good time running this National Championship event, and I look forward to running with Texas TT3 guys like Costas in the G-SPEED C5 and Adam in his EVO again next season.

POST NATS PLANS, UPGRADES & REPAIRS

We got back from COTA with the big spacers on, and the tire poke was KILLING me. Why does any amount of tire sticking past the fenders matter? Well in reality its not that big of a deal - if you have sufficient clearance at full bump travel. The #CheaterC5 had gone to 335mm fronts (from 315s) between the May and September events, with just cut fenders, and it was still plenty fast.

Left: #HellaPoke! Right: At full bump travel and loaded in a corner, the outside tires were very close to the fender lips!

But having the tires sticking out past the fender lip can cause tire damage when going over a big bump. Luckily when our car loaded up in corners, the sloppy rubber suspension bushings loaded up and pushed the wheels inboard enough that the outside tires it just barely cleared the fenders (see above). Man it was close!

Still, going down the straights with a spinning tire sticking out in the air stream, especially the fronts, adds a lot of drag. We often make fairings that blend into the flares/front cover (or even just basic "tire walls") to cover up the leading edges of the front tires - like we did on our TTD/TT4 BMW E46, above. That is something we need to address on the S550, eventually. We may or may not do big aero on this car...

Changing from 1/2" to 1/4" spacers made a big difference, above

I asked Evan to look at the rear E-brake cables (which was where the rear tires touched inboard). Those got bent out of the way (just a few gentle taps with a 5 lb sledge) and now we have 1/4" more inboard rear room (see below left). Then we swapped out the front spacers to smaller 1/4" thick units, and the #HellaPoke is much removed (see above).

Up front was a balancing act between the strut-to-spindle slotted connection and opening up the strut top hole. The strut brackets almost always has one slotted hole, especially on aftermarket coilovers. We will show how to "fine tune" this interface for the ideal tire clearance + camber in the next thread update. With these splined spindle mounting bolts, it is tricky (above right), but possible.

I'll show more of the strut tower opening next time, but we made a new series of tools that we will sell soon for the S197 and then another for the S550 towers. These bolt in place of the top mount and line up a hole saw.

We chose a 2-3/4" hole saw and cut the towers on my 2018 GT here. This allows a good bit more camber travel as well as caster travel. With the MCS RR2 struts in place we can kick the top of the strut a lot more inboard now. This allows the strut-to-spindle junction to push outwards for more inboard wheel room to the strut.

We took the Hoosiers off the 19x11" wheels (above left) - they looked great and should give us another competitive weekend or two of NASA events, with careful tire management. The RE-71R tires (above right) were re-mounted to the same 19x11 wheels again. I had them flipped relative to the wheels, and after 7 events/weekends there is plenty of rubber left. Still has a good durometer number, too.

We have a few street tire events lined up (to test the Ohlins coilovers we just added), then a NASA event at the very end of October (back on MCS RR2s). By then we hope to have our new MOMO wheels (Heritage 6 in 18x11, above left, and RF-20 in 19x11, above right) on hand, to be able to swap tires and wheels more easily. The plan is move (the next new set of) Hoosiers to the 18x11 set and keep running 305/30/19 street tires on the 19x11 wheels.

The brakes looked great after COTA. Again, braking was the BEST thing about the car at Nationals. Could always pass other cars into a braking zone, if I needed to. Made a LOT of passes T1, T11 and T12. Temp paint on the rotors and temp strips on the calipers showed that we were in the right heat ranges. The Powerbrake PB13 front pads had good bite without upsetting the ABS tuning in the wet. Going to keep these going on the front for a while. Rears are R16, very aggressive compound, but it's working.

We have another set of dampers on the car right now, Ohlins R&T, for a track test and some other events in the next month. The MCS dampers are going back on the car for a NASA event in late October, with a few small tweaks to the rears. Will share more of all of that next time.

continued below

- Results: http://timingscoring.drivenasa.com/...ips Presented by Toyo Tires/Official Results/

- NASA write-up about TT: https://nasaspeed.news/race-coverag...announces-2018-time-trial-national-champions/

- Vorshlag photo gallery: https://vorshlag.smugmug.com/Racing-Events/NASA-Nationals-COTA-091418/

Amy was my rock over the 3 day Nationals weekend - she could have driven on Team Vorshlag but due to the limited number of dry sessions she let me drive them all. She kept me hydrated and fed between sessions, helped with tire changes, took pictures, everything. The weather was a constant challenge but everyone had to deal with it, and we got our two dry TT sessions. There was a little drama, and a car that was handicapped a bit (oil temps & rear shocks), but I was damn happy to run a 2:28 lap in a heavy car, with a bone stock engine, AC, zero aero, and that was still street legal. I used the AC on many occasions!

We had a good time running this National Championship event, and I look forward to running with Texas TT3 guys like Costas in the G-SPEED C5 and Adam in his EVO again next season.

POST NATS PLANS, UPGRADES & REPAIRS

We got back from COTA with the big spacers on, and the tire poke was KILLING me. Why does any amount of tire sticking past the fenders matter? Well in reality its not that big of a deal - if you have sufficient clearance at full bump travel. The #CheaterC5 had gone to 335mm fronts (from 315s) between the May and September events, with just cut fenders, and it was still plenty fast.

Left: #HellaPoke! Right: At full bump travel and loaded in a corner, the outside tires were very close to the fender lips!

But having the tires sticking out past the fender lip can cause tire damage when going over a big bump. Luckily when our car loaded up in corners, the sloppy rubber suspension bushings loaded up and pushed the wheels inboard enough that the outside tires it just barely cleared the fenders (see above). Man it was close!

Still, going down the straights with a spinning tire sticking out in the air stream, especially the fronts, adds a lot of drag. We often make fairings that blend into the flares/front cover (or even just basic "tire walls") to cover up the leading edges of the front tires - like we did on our TTD/TT4 BMW E46, above. That is something we need to address on the S550, eventually. We may or may not do big aero on this car...

Changing from 1/2" to 1/4" spacers made a big difference, above

I asked Evan to look at the rear E-brake cables (which was where the rear tires touched inboard). Those got bent out of the way (just a few gentle taps with a 5 lb sledge) and now we have 1/4" more inboard rear room (see below left). Then we swapped out the front spacers to smaller 1/4" thick units, and the #HellaPoke is much removed (see above).

Up front was a balancing act between the strut-to-spindle slotted connection and opening up the strut top hole. The strut brackets almost always has one slotted hole, especially on aftermarket coilovers. We will show how to "fine tune" this interface for the ideal tire clearance + camber in the next thread update. With these splined spindle mounting bolts, it is tricky (above right), but possible.

I'll show more of the strut tower opening next time, but we made a new series of tools that we will sell soon for the S197 and then another for the S550 towers. These bolt in place of the top mount and line up a hole saw.

We chose a 2-3/4" hole saw and cut the towers on my 2018 GT here. This allows a good bit more camber travel as well as caster travel. With the MCS RR2 struts in place we can kick the top of the strut a lot more inboard now. This allows the strut-to-spindle junction to push outwards for more inboard wheel room to the strut.

We took the Hoosiers off the 19x11" wheels (above left) - they looked great and should give us another competitive weekend or two of NASA events, with careful tire management. The RE-71R tires (above right) were re-mounted to the same 19x11 wheels again. I had them flipped relative to the wheels, and after 7 events/weekends there is plenty of rubber left. Still has a good durometer number, too.

We have a few street tire events lined up (to test the Ohlins coilovers we just added), then a NASA event at the very end of October (back on MCS RR2s). By then we hope to have our new MOMO wheels (Heritage 6 in 18x11, above left, and RF-20 in 19x11, above right) on hand, to be able to swap tires and wheels more easily. The plan is move (the next new set of) Hoosiers to the 18x11 set and keep running 305/30/19 street tires on the 19x11 wheels.

The brakes looked great after COTA. Again, braking was the BEST thing about the car at Nationals. Could always pass other cars into a braking zone, if I needed to. Made a LOT of passes T1, T11 and T12. Temp paint on the rotors and temp strips on the calipers showed that we were in the right heat ranges. The Powerbrake PB13 front pads had good bite without upsetting the ABS tuning in the wet. Going to keep these going on the front for a while. Rears are R16, very aggressive compound, but it's working.