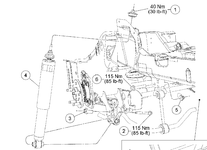

Hey all, this is my first post to TMO, I’ve been lurking for the past year or so learning a lot thanks to all the great threads posted and seeing what you all have been up to on your cars. I recently installed coilovers on my ‘14 and over some time shredded my rear upper shock bushings most likely due to me over tightening the nut. I have replacements here but i’m unsure how tight I should make the nut and wanted to see what you guys say. I keep seeing multiple sources say to tighten it until the bushing slightly bulges bigger than the washer, but this bushing is already a bit bigger as well as being a more conical kind of shape. Any second opinions are greatly appreciated and sorry if I posted incorrectly or anything like that.