- Thread starter

- #1,381

Fabman

Dances with Racecars

- 6,553

- 8,204

- Exp. Type

- W2W Racing

- Exp. Level

- 20+ Years

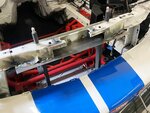

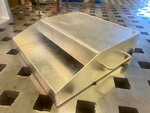

Its getting there. One more little detail before i can install this then its go time.Now get it in the beast and get that thing on the track! Am waiting for my final tune (hopefully) from Shaun and off to the dyno we go.