Getting ready to assemble the refreshed motor but I only have the timing procedure for Voodoo crank. Thanks!

- Welcome to the Ford Mustang forum built for owners of the Mustang GT350, BOSS 302, GT500, and all other S550, S197, SN95, Fox Body and older Mustangs set up for open track days, road racing, and/or autocross. Join our forum, interact with others, share your build, and help us strengthen this community!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

anyone have the timing procedure for the 5.2 XS/FP350S

- Thread starterhoneybadger

- Start date

This site may earn a commission from merchant affiliate links, including eBay, Amazon, and others.

More options

Who Replied?- Thread starter

- #3

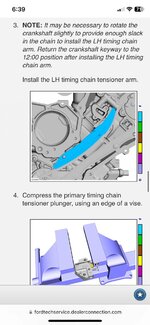

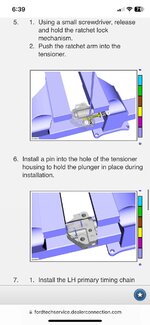

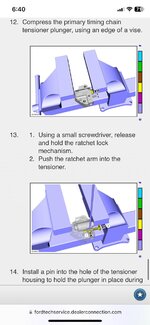

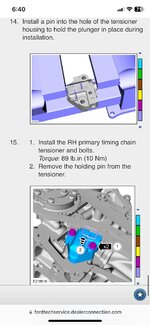

So first off, wanted to say thanks for getting this over to me.Here you go. First step got cut off. It is to rotate crankshaft clockwise until the keyway is at 5 o'clock position.

Second, wanted to start a broader convo. So to recap, I using a Voodoo motor being converted over to CPC. It uses a predator crank (part # KR3Z-6303-B) and CPC-version of voodoo cams from L&M engine cams (https://lmengines.com/collections/gt350-camshafts/products/gt350-voodoo-w-90-deg-cross-plane-crank)

All other parts are original equipment voodoo (GT350R phasers, followers, lifters, timing chains, tensioners, etc.). When i went to time the motor using the instructions above - there was clear piston to valve contact and the motor would not full turnover (at least without a tremendous amount of pressure).

Someone on instagram recommended I try the original voodoo timing - so I followed that to a tee and sure enough it worked. Engine turns over easy, no contact, etc. I'm perplexed. only thing I can think of is where the keyways on the phasers/cams are is identical to the voodoo cams. But open to feedback

The cam/phaser keyways are the same for both FPC and CPC, remember the Voodoo originally came with coyote phasers.

Is it possible they sent you the wrong cams? Rotate the engine over and follow the intake valve opening sequence or compression stroke sequence to check the firing order. CP is 1-5-4-8-6-3-7-2.

Is it possible they sent you the wrong cams? Rotate the engine over and follow the intake valve opening sequence or compression stroke sequence to check the firing order. CP is 1-5-4-8-6-3-7-2.

Last edited:

And here I was, wondering if the engine would only run if it was turning backwards...The cam/phaser keyways are the same for both FPC and CPC, remember the Voodoo originally came with coyote phasers.

Is it possible they sent you the wrong cams? Rotate the engine over and follow the intake valve opening sequence or compression stroke sequence to check the firing order. CP is 1-5-4-8-6-3-7-2.

- Thread starter

- #6

okay, so am I a super dunce/losing my mind? also possible I completely don't understand engines - at this point I'm not sure this isn't a dream. appreciate the help - I'm a hands on learner and need some commentary/explaination on what I am looking at in my garage.

youtube.com

youtube.com

5.2 CPC timing

Maybe the cut the keyways in the cams correctly to allow for this type of conversion scenario. So that all you had to do was swap cranks? That would seem too easy.

You're not loosing your mind, those Intake valve events are correct. However, 1-5-4-8 is the same for both FPC and CPC, it's the last 4 that are different. The FPC continues 3-7-2-6 vs. 6-3-7-2 for the CPC.okay, so am I a super dunce/losing my mind? also possible I completely don't understand engines - at this point I'm not sure this isn't a dream. appreciate the help - I'm a hands on learner and need some commentary/explaination on what I am looking at in my garage.

5.2 CPC timing

youtube.com

After #8, it's either #3 or #6 intake that is opening.

Looking at your video, I'd say you have CPC cams.

Last edited:

- Thread starter

- #9

video showing 6 and 3. It looks like everything is correct to me.

Only thing I can think of is the keyways on the cams like Stan mentioned.

one thing I need to verify - so firing order is 1-5-4-8-6-3-7-2 as @bauern mentioned. So to verify that the exhaust/intake valves are opening in the right order in relation to the firing order, so if I chase finding TDC for each of those cylinders in that order, the intake valve will have just finished its cycle of opening, correct? Because chasing the TDC for each cylinder in the firing order is completing two full rotations of the crank, correct?

Last edited:

I can't see that the cam keyways would be changed, L&M would have to supply special instructions with their cams if so. You'll have to contact them to check.

video showing 6 and 3. It looks like everything is correct to me.

Only thing I can think of is the keyways on the cams like Stan mentioned.

one thing I need to verify - so firing order is 1-5-4-8-6-3-7-2 as @bauern mentioned. So to verify that the exhaust/intake valves are opening in the right order in relation to the firing order, so if I chase finding TDC for each of those cylinders in that order, the intake valve will have just finished its cycle of opening, correct? Because chasing the TDC for each cylinder in the firing order is completing two full rotations of the crank, correct?

Yes it will take 2 full crank rotations and you can chase the firing order that way but I wouldn't try to confirm valve opening events and TDC that way.

- Thread starter

- #11

Do you have a recommendation on how to confirm valve opening events?I can't see that the cam keyways would be changed, L&M would have to supply special instructions with their cams if so. You'll have to contact them to check.

Yes it will take 2 full crank rotations and you can chase the firing order that way but I wouldn't try to confirm valve opening events and TDC that way.

Degree wheel and dial indicator.

If I was in your position, and I was, I would take the timing parts off - chains, phasers, cams - and redo it.

I was in the process of changing the oil pump on the Voodoo engine but mixed up the coyote and voodoo instructions. When I removed the Driver side chains the cams rotated out of position because of spring pressure. Tried to put them back in position and reassembled everything. Hard starting, ran like shiznit, wouldn't idle and threw codes. Was frustrated but only real solution was to remove everything and start from scratch.

If I was in your position, and I was, I would take the timing parts off - chains, phasers, cams - and redo it.

I was in the process of changing the oil pump on the Voodoo engine but mixed up the coyote and voodoo instructions. When I removed the Driver side chains the cams rotated out of position because of spring pressure. Tried to put them back in position and reassembled everything. Hard starting, ran like shiznit, wouldn't idle and threw codes. Was frustrated but only real solution was to remove everything and start from scratch.

- Thread starter

- #13

Oh - I timed it like 4 times.I tried the way you provided up above 3 times the first night and came back a day later and re-did it. Got it fully assembled and didn't like the way it would spin. You could feel piston to valve contact and see that it was trying to open valves with pistons moving up.Degree wheel and dial indicator.

If I was in your position, and I was, I would take the timing parts off - chains, phasers, cams - and redo it.

I was in the process of changing the oil pump on the Voodoo engine but mixed up the coyote and voodoo instructions. When I removed the Driver side chains the cams rotated out of position because of spring pressure. Tried to put them back in position and reassembled everything. Hard starting, ran like shiznit, wouldn't idle and threw codes. Was frustrated but only real solution was to remove everything and start from scratch.

In a moment of desperation, I took it apart and and re-timed per the Voodoo instructions and it worked. Here's a video of a full 2x rotations with valves opening.

at this point - all I feel like I know is that the timing instructions (re: positions of the crank/cams) are different for the 5.0, CPC 5.2, and FPC 5.2

I would be very leery of running the engine timed that way. The 5.0 coyote and 5.2L CPC are interchangeable; the rod pin location is the same in all views (other than stroke length). I can't see of any reason for a hybrid method.

- Thread starter

- #15

are you sure they're interchangeable? this is what was shared with me for the GT500 and it's different than the 5.0 instructions you shared. Not only does the GT500 use 1230 and 11 o clock positions on the crank, it doesn't say anything about a complete revolution (5.0 instructions say 5 o clock position for LH, then one full rotation and clockwise until 12 o clock - which is 1.5 rotations).I would be very leery of running the engine timed that way. The 5.0 coyote and 5.2L CPC are interchangeable; the rod pin location is the same in all views (other than stroke length). I can't see of any reason for a hybrid method.

- Thread starter

- #16

update - got some clear instructions from Mike at L&M today - going to re-timing it per those instructions and see how it goes. Will post results

Interested in seeing them.

After you installed the phasers on the cams did you have to rotate the cams to put the timing marks in the position indicated by the 5.0 instructions above?

After you installed the phasers on the cams did you have to rotate the cams to put the timing marks in the position indicated by the 5.0 instructions above?

- Thread starter

- #18

Okay - successfully timed the engine last night per Mike's instructions. Essentially, it's timed per the 2015-2017 5.0 timing, but using a different procedure. Not a single clue how I couldn't get the service manual way to work - literally tried 4 times and had contact of piston to valve each time.

But the method from L&M worked and I'd recommend it going forward. Easier than the Ford anyways.

Here's a link to the official instructions. https://cdn.shopify.com/s/files/1/0075/1131/0433/files/2015_Cam_Timing_Instructions.pdf?1264

Essentially, put the crank keyway at 12o'clock. This puts the pistons at position where no valves can contact the pistons. So you're free to rotate the cams - which is easier than trying to tighten them down under pressure anyways.

Here's the orientation i started with before I went to put the phasers on. Exhaust ended up needing to be rotated about 20 degrees counter-clockwise to slip the phaser on

Phasers start like this, then rotated 90 degrees to the left

Here's how it looked with the LH side fully installed - LH mark is at 12 o'clock (using deck of the head as reference - probably 2 o'clock using photo orientation as reference).

Here's where I started on the RH side. Basically cams in opposite orientation. This side was much easier. All cam lobes are unloaded - so completely neutral position

Phasers went on without an rotation

After getting the RH side on - I verified position by putting cylinder #1 at TDC and compared the cam lobe positions to the photos that Mike sent me. These are verified. so if your lobes match these - you are good to go.

Here's a video if that's you're preferred learning style

But the method from L&M worked and I'd recommend it going forward. Easier than the Ford anyways.

Here's a link to the official instructions. https://cdn.shopify.com/s/files/1/0075/1131/0433/files/2015_Cam_Timing_Instructions.pdf?1264

Essentially, put the crank keyway at 12o'clock. This puts the pistons at position where no valves can contact the pistons. So you're free to rotate the cams - which is easier than trying to tighten them down under pressure anyways.

Here's the orientation i started with before I went to put the phasers on. Exhaust ended up needing to be rotated about 20 degrees counter-clockwise to slip the phaser on

Phasers start like this, then rotated 90 degrees to the left

Here's how it looked with the LH side fully installed - LH mark is at 12 o'clock (using deck of the head as reference - probably 2 o'clock using photo orientation as reference).

Here's where I started on the RH side. Basically cams in opposite orientation. This side was much easier. All cam lobes are unloaded - so completely neutral position

Phasers went on without an rotation

After getting the RH side on - I verified position by putting cylinder #1 at TDC and compared the cam lobe positions to the photos that Mike sent me. These are verified. so if your lobes match these - you are good to go.

Here's a video if that's you're preferred learning style

Last edited: