When did your engine blowup?

- Welcome to the Ford Mustang forum built for owners of the Mustang GT350, BOSS 302, GT500, and all other S550, S197, SN95, Fox Body and older Mustangs set up for open track days, road racing, and/or autocross. Join our forum, interact with others, share your build, and help us strengthen this community!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

High oil temp (overheating at track)

- Thread starterSGwick

- Start date

This site may earn a commission from merchant affiliate links, including eBay, Amazon, and others.

More options

Who Replied?captdistraction

GrumpyRacer

Lap 7. Though temp at time of failure was 240. I actually think it may have been some vibration with those off readings now that I’ve reviewed. I don’t think the engine was overheating in any way as the cyl head temp was constant lap to lap

That said I’m definitely interested in cooler capacity but I’ll put up a link to where anyone can publicly review my data through a web interface

That said I’m definitely interested in cooler capacity but I’ll put up a link to where anyone can publicly review my data through a web interface

I was more wondering if the oil temp increase was indicative of the failure chain versus being the cause.

captdistraction

GrumpyRacer

Possibly but I did find the sensor/sender connector a bit loose.

Certainly possible that it was indeed the case warmer oil though I didn’t find any bearings showing unusual wear. Rod bearings looked reasonable, mains looked fresh, cam bearings looked great, cylinders looked great plugs looked like new as only had a couple hours on them.

Certainly possible that it was indeed the case warmer oil though I didn’t find any bearings showing unusual wear. Rod bearings looked reasonable, mains looked fresh, cam bearings looked great, cylinders looked great plugs looked like new as only had a couple hours on them.

captdistraction

GrumpyRacer

possibly, I was catching the people in front but I'd still call that free clean air. Possibly vibration driven heat issues, but causes still unknown. I'll keep working on that in the other thread

That said, for future motors and cooling The Setrab

948: 16"x14.75", 1.8 PSI drop, 69,000 BTU

934: 16"x10.5", 2.3 PSI drop, 53,000 BTU

Is there anything else I should consider?

Right now I'm running the 915: 16"x5", 4.5psi drop, 27,000 BTU plus the boss cooler (which I've heard is roughly 4500 btu with a decent radiator).

Also, is -10AN enough?

That said, for future motors and cooling The Setrab

948: 16"x14.75", 1.8 PSI drop, 69,000 BTU

934: 16"x10.5", 2.3 PSI drop, 53,000 BTU

Is there anything else I should consider?

Right now I'm running the 915: 16"x5", 4.5psi drop, 27,000 BTU plus the boss cooler (which I've heard is roughly 4500 btu with a decent radiator).

Also, is -10AN enough?

Somewhere on a forum far far away, there's a discussion thread about this very issue. Ford Racing (as they were known at the time) recommended -12AN (3/4") lines for racing applications with their remote filter adapter. I have a vague memory of Dean Martin's name coming up in the thread, so maybe ask him....Also, is -10AN enough?

The other thing to look at is whether it's still a good idea to have the oil/water cooler. I had one and the openings look mighty small for the oil to go through. If you have enough oil-to-air cooling you might be better off without it.

captdistraction

GrumpyRacer

left a message on their facebook group. Will see how it goes.

I use the 934 and no cooling ducts (2012) temps have gone from 290-300 down to 260 max last year, I was and am measuring at the oil filter adapter were the oil returns from the cooler. The stock oil cooler is still in place, no other changes. I am happy with the results.

Grant 302

basic and well known psychic

plus the boss cooler (which I've heard is roughly 4500 btu with a decent radiator).

You all are more serious track folks, but got the car out for 10+ days of HPDE last year and battled the great temp issues the car gives us particularly at high rpm - coolant temp was the limiter for me because of the Ford oil/coolant cooler. After a bunch of calculations, etc. ultimately I found a nice summary that was darn close to my calculations to help selection https://www.pegasusautoracing.com/pdfs/SetrabApplicationSuggestions.pdf This coupled with suggestions from Black Boss (thank you - his recommendation is Setrab 948) and looking at Swiss Boss (Setrab 660) and Voodoo Boss (934) installs.

Capacity of 948/660 along are the 60 to 90k BTU range with pressure drop being slightly different.

I settled on using the Setrab 660 with AN-10 lines and removed the Ford oil/coolant to eliminate cooling demand; already put in the Ford Performance radiator during last season (min improvement) and just added the higher performance fan - want to stop gage watching this season. Being up in Chicago our season hasn't started yet so can't verify it works yet, but all of those guys have had good success. For your issue, take a look at the coolant temp (after 2 laps that rises fast) and your rpm to see if less cooling and more heat was being put in for that lap (based on the pics, you are likely more knowledgeable & already looked into this) P.s. this is my first post so feel free to critiqueGrant 302

basic and well known psychic

Welcome @chicagobob! Willingness to help makes a great first post in my opinion. Do you have some oil temp data from before and after you put in the Setrab 660?

TMSBOSS

Spending my pension on car parts and track fees.

Bob, Welcome!

The single most effective cooling mod for my Boss was swapping out the grill. Allowing more air to pass through the radiator and coolers was key.

Will you be at the Track night at Blackhawk in May?

The single most effective cooling mod for my Boss was swapping out the grill. Allowing more air to pass through the radiator and coolers was key.

Will you be at the Track night at Blackhawk in May?

Remove grille or high-flow grille. Large oil cooler as you have mentioned. If you are switching out radiator, go to the C&R / PWR unit--it is expensive but it does work. The FRPP radiator was about as good as the stock Boss radiator, the C&R dropped my ECTs around 20*F by comparison--because there is more radiator surface area exposed to the lower grille where (surprisingly) most of the cooling airflow comes from.

Beyond that the next step (or you can do this today for some extra help) is to box in the radiator area. Both @Black Boss and I have information on that buried in our build threads.

Beyond that the next step (or you can do this today for some extra help) is to box in the radiator area. Both @Black Boss and I have information on that buried in our build threads.

Mad Hatter

Gotta go Faster

Good to know about FRPP was only as good as the Boss rad! Waiting for my oil temp and pressure gauges to arrive so I can finally see what they are at. Removing my grill brought down the needle right away, and it stays down for 20min sessions even on 90 degree plus days.

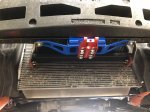

The addition of the Setrab660, removal of the oil/coolant, and addition of an oil temp sensor were done over the winter, so no new data yet until get it out to the track at the end of the month. Run time permitting I will plan on gathering some A-B comparisons with the oil cooler blocked and open oil cooler (temp sensor near the sandwich plate pre-cooler) - not the greatest comp, but will see what the cooler is doing. In the past the monitoring was from the OBDII coolant temp (yes inferred temp) which would rise to mid-240's after two hard higher rpm laps, then needed to cool down with some momentum laps keeping the rpm down and working on lines - good part was never went to limp mode. Here are some of the early install pictures.Welcome @chicagobob! Willingness to help makes a great first post in my opinion. Do you have some oil temp data from before and after you put in the Setrab 660?

Attachments

Thanks for the welcome. Good advice on the grille, the high flow / no grille option is definitely the next item and easiest if needed (the current GT with rally lights is certainly on the low flow side).Bob, Welcome!

The single most effective cooling mod for my Boss was swapping out the grill. Allowing more air to pass through the radiator and coolers was key.

Will you be at the Track night at Blackhawk in May?

In line with Arizona Boss, on the radiator, mid-season went from the stock GT (less capacity than the Boss) to the FRPP and saw some improvement in the OBDII coolant temps, estimate <10 deg better at similar track load conditions which gave a small improvement in time before heat soak, but not a game changer. The main improvement was faster recover, once the rpm got down reducing coolant load from the oil/coolant oil cooler, the coolant temps came down faster so could manage hard laps and recovery laps better, but wouldn't have started with the radiator in the beginning and didn't solve the problem.

First track day circled on the schedule is Road American at the end of April with NWSC - hoping for ok weather which is spotty for us folks up north. Which May Blackhawk day are you referencing?

- 680

- 215

I think boxing in the radiator ( beyond factory sealing ) probably is one of the best changes that is not talked about much...Remove grille or high-flow grille. Large oil cooler as you have mentioned. If you are switching out radiator, go to the C&R / PWR unit--it is expensive but it does work. The FRPP radiator was about as good as the stock Boss radiator, the C&R dropped my ECTs around 20*F by comparison--because there is more radiator surface area exposed to the lower grille where (surprisingly) most of the cooling airflow comes from.

Beyond that the next step (or you can do this today for some extra help) is to box in the radiator area. Both @Black Boss and I have information on that buried in our build threads.

Grant 302

basic and well known psychic

The addition of the Setrab660, removal of the oil/coolant, and addition of an oil temp sensor were done over the winter, so no new data yet until get it out to the track at the end of the month. Run time permitting I will plan on gathering some A-B comparisons with the oil cooler blocked and open oil cooler (temp sensor near the sandwich plate pre-cooler) - not the greatest comp, but will see what the cooler is doing. In the past the monitoring was from the OBDII coolant temp (yes inferred temp) which would rise to mid-240's after two hard higher rpm laps, then needed to cool down with some momentum laps keeping the rpm down and working on lines - good part was never went to limp mode. Here are some of the early install pictures.

Nice brackets and installation. Removal of the 'Boss' cooler will certainly help with lowering the coolant temps. Looking forward to your comparison.

Similar threads

- Replies

- 5

- Views

- 1K

- Replies

- 0

- Views

- 497